Leave Your Message

The demand for efficient handling equipment continues to rise. The global market for motorized pallet jacks is expected to reach $3 billion by 2026. This surge reflects the industry's need for improved productivity and safety.

Motor pallet jacks are becoming critical in various sectors. They offer faster movement of goods than manual options. A 2022 report noted that companies using motor pallet jacks improved their warehouse efficiency by nearly 30%. However, challenges remain in understanding their full capabilities.

Many users overlook essential features. They might not realize the importance of battery life or load capacity. These elements greatly impact operational effectiveness. Ensuring proper utilization of motor pallet jacks can lead to substantial cost savings. Investing in the right equipment is crucial for modern logistics.

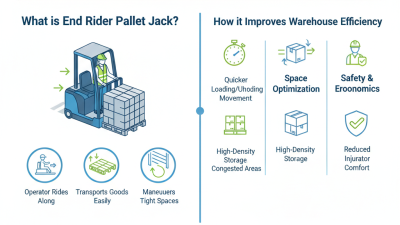

Motor pallet jacks are essential tools in modern warehouses. They efficiently move heavy loads, enhancing productivity. These machines often feature electric-driven motors, making them easier to operate. Operators can control movement with a simple handle, reducing physical strain. This is especially beneficial in environments that require lifting and transporting goods frequently.

Adjustable forks allow for versatility in handling various pallet sizes. Safety features, such as emergency brakes and stable platforms, can prevent accidents. Operators must remember, though, that improper use can lead to injuries. Training is crucial to maximize safety and efficiency. The balance of the load must also be monitored actively.

In addition to ease of use, motor pallet jacks are designed for durability. High-quality materials ensure they can withstand heavy-duty tasks over time. However, maintenance is often overlooked. Regular checks on battery life and wear can prevent unexpected failures. Operators should keep an eye on these details for a smooth operation. Ignoring them can lead to downtime and operational issues.

This chart illustrates the key features and benefits of motor pallet jacks in 2026. The data compares four essential attributes: Load Capacity, Battery Life, Maneuverability, and Maintenance Cost. Each category showcases the significance of motor pallet jacks in modern warehousing and logistics operations.

When considering the 2026 motor pallet jacks, several key features stand out. One noticeable aspect is their ergonomic design. These jacks are built to reduce strain during operation. Operators can handle heavy loads more comfortably, which is essential for efficiency. The adjustable handle height further enhances comfort, allowing users of various heights to work without discomfort.

Speed and maneuverability are also crucial. The new models come with advanced motors, enabling faster lifting and lowering cycles. This is significant in busy warehouse settings where time is money. Additionally, improved turning radiuses allow easy navigation in tight spaces. Users often mention the frustration of maneuvering bulky equipment. This design mitigates that issue, though it may take time to fully adjust to the new capabilities.

Some users have pointed out potential shortcomings. Battery life can be a concern in high-demand scenarios. There may be hesitation about how often charging will interrupt workflows. Furthermore, the weight distribution of loads can affect handling. It’s an area that requires vigilance. Overall, the developments in motor pallet jacks are promising, though users must adapt to maximize their potential.

| Feature | Description | Benefits |

|---|---|---|

| Ergonomic Design | Designed to reduce strain on the user. | Improves comfort during operation, reducing fatigue. |

| Electric Power | Battery-operated for effortless mobility. | Enhances efficiency and reduces effort compared to manual jacks. |

| Lift Capacity | Able to lift up to 5500 lbs. | Suitable for heavy-duty lifting tasks. |

| Compact Size | Space-saving design for maneuverability. | Ideal for tight spaces and small warehouses. |

| Safety Features | Includes anti-slip forks and emergency stop. | Minimizes accident risk during operation. |

| User-Friendly Controls | Simple control panel for ease of use. | Reduces learning time for new operators. |

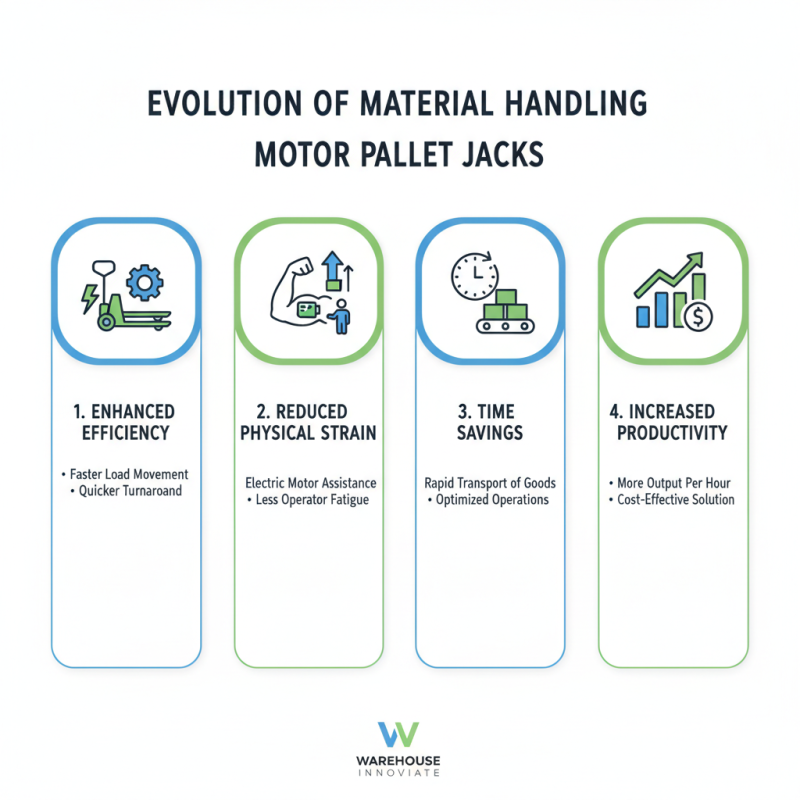

Motor pallet jacks are evolving in the world of material handling. These tools significantly enhance efficiency in warehouses and distribution centers. Their electric motors reduce the physical strain on employees. Operators can move large loads quickly, which saves time. This speed can lead to increased productivity throughout the operation.

The use of motor pallet jacks also promotes safety. Traditional manual jacks can be hard to control under heavy loads. Electric options often come with features like automatic braking and ergonomic designs. However, training is essential. Improper use can lead to accidents, emphasizing the need for proper handling techniques.

Another aspect to consider is maintenance. While motor pallet jacks require more attention than manual versions, the benefits often outweigh the costs. Regular checks on the electrical components and battery life are crucial. Neglecting maintenance can lead to downtime, which can be costly. Careful consideration of these factors will enhance the advantages of motor pallet jacks in any operation.

Motor pallet jacks have become essential tools in various industries. When comparing different models, several factors stand out. First, consider their lifting capacity. Some models can lift heavier loads, while others excel in maneuverability. Users often face challenges in finding the right balance.

Another aspect to examine is battery life. A longer battery life usually means fewer interruptions during work. However, some models may take longer to recharge, making downtime an issue. It's crucial to think about how often you will use the pallet jack.

Tips for choosing the right model include checking user reviews. Their experiences can highlight both strengths and limitations of each model. Also, think about the type of terrain the jack will navigate. Some work better on smooth surfaces, while others can handle rough terrain. Visualize your workspace before making a decision. It can save you from future headaches.

The future of motor pallet jack technology is evolving rapidly. Industry reports indicate a shift toward increased automation. Features such as smart sensors are becoming standard. These sensors can detect load weight and ensure optimal safety during operations. According to market analysis, the global motor pallet jack market is expected to grow by 5.9% annually until 2026.

Battery technology is also advancing. Lithium-ion batteries are being adopted for their longevity and efficiency. They reduce downtime significantly due to faster charging. Studies suggest that these batteries can last up to twice as long as traditional lead-acid options. However, the higher initial cost may deter some buyers.

Design plays a critical role in user experience. Ergonomically designed handles can reduce strain during prolonged use. Still, there are issues with balancing weight distribution in some models. Companies need to address these concerns to optimize functionality. The integration of IoT is on the rise, but not all users may be ready for such complexity. Simplicity remains key, yet innovation is essential for staying competitive.