Leave Your Message

In the ever-evolving landscape of warehouse operations, the integration of advanced technologies has become a cornerstone of efficiency and productivity. As we move further into 2025, the adoption of automatic pallet jacks, known in the industry as "Pallet Jack Automatic", is witnessing a significant surge. According to a recent report from the Warehousing Association, the use of automated material handling equipment is projected to increase by 25% over the next few years, highlighting a pivotal shift towards automation in logistics and supply chain management.

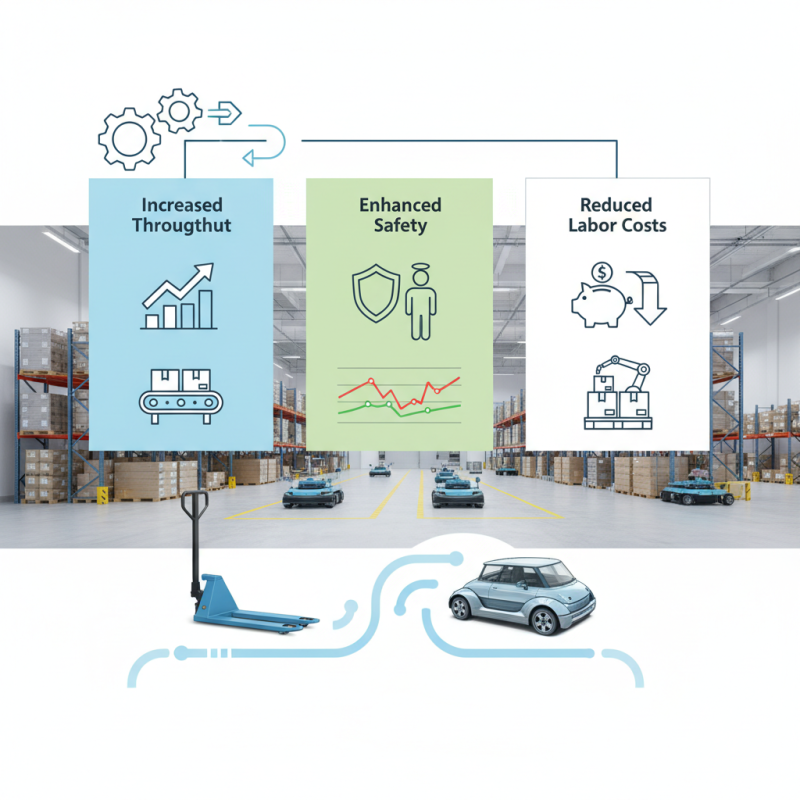

Industry expert Dr. Emily Carter, a noted authority on warehouse automation, emphasizes the transformative impact of these tools: “The introduction of Pallet Jack Automatic systems not only streamlines operations but also enhances safety and reduces labor costs.” These automated solutions are designed to minimize manual handling, optimize space utilization, and improve workflow efficiency, enabling warehouses to respond swiftly to the dynamic demands of the market.

As businesses strive to maintain competitiveness in a fast-paced environment, understanding the top benefits of utilizing Pallet Jack Automatic systems will be essential for achieving operational excellence. From increased throughput to reduced risk of workplace injuries, the advantages are manifold and underline the crucial role automation plays in modern warehouse management practices.

Automatic pallet jacks are increasingly becoming integral tools in modern warehousing, enhancing efficiency and productivity in operations. One of the significant advantages of using these automated devices is their ability to minimize manual labor. By automating the lifting and transporting of heavy pallets, warehouses can reduce the risk of worker injuries, leading to a safer work environment. Additionally, these jacks can operate in tighter spaces, allowing for better space utilization and optimized warehouse layouts.

Another crucial benefit of automatic pallet jacks is their impressive speed and accuracy in handling stock. Compared to traditional manual jacks, automated versions can move goods quickly and perform repetitive tasks with precision, which significantly cuts down on the time required for inventory management. This time efficiency translates into quicker turnaround times and better service levels for customers, ultimately impacting the warehouse's bottom line positively.

Tips: To maximize the benefits of automatic pallet jacks, it's essential to provide adequate training for operators. Ensuring that employees understand the technology and safety protocols will enhance productivity and prevent potential errors. Additionally, regular maintenance checks can help keep the equipment in optimal working condition, ensuring longevity and reliability in daily operations.

The following chart illustrates the anticipated benefits of using automatic pallet jacks in warehouse operations by 2025. This includes improvements in efficiency, safety, and reduced operational costs.

The landscape of warehouse operations is set to transform dramatically in 2025, and automatic pallet jacks are at the forefront of this evolution. These advanced machines significantly enhance efficiency by automating the process of transporting goods, reducing the physical strain on workers while improving throughput. With real-time data integration and smart technology, automatic pallet jacks can optimize routes within the warehouse, allowing for faster and more efficient movement of inventory. This not only saves time but also minimizes the risk of human error, ensuring a smoother workflow.

In addition to improving transport speed, automatic pallet jacks contribute to a safer working environment. Equipped with sensors and safety features, they can detect obstacles and adapt to their surroundings, reducing the likelihood of accidents. This is particularly important in busy warehouse settings where the movement of personnel and machinery occurs simultaneously. Moreover, automation can lead to better space utilization within the warehouse, as these machines can operate in tighter areas and streamline the stacking process, thus maximizing storage capacity. The combination of enhanced efficiency and improved safety makes automatic pallet jacks an essential component of modern warehouse operations in 2025 and beyond.

In the fast-evolving landscape of warehouse operations, the adoption of automatic pallet jacks is becoming increasingly pivotal in reshaping labor dynamics. By automating the movement of goods, these advanced tools significantly reduce the physical strain on workers. This automation allows employees to focus on more critical tasks, fostering a safer work environment while simultaneously enhancing operational productivity. As warehouses look to streamline processes in 2025, automatic pallet jacks emerge as a vital asset in minimizing manual labor requirements.

The impact on labor costs is particularly noteworthy. With the minimized need for manual handling, companies can reallocate their workforce to areas that require more complex decision-making and skill sets. This shift not only leads to a reduction in labor costs associated with repetitive, low-skilled tasks but also empowers employees to acquire new skills that can enhance their career trajectories. Overall, the introduction of automatic pallet jacks enables warehouses to trim labor expenses while cultivating a more efficient, skilled workforce capable of adapting to the swiftly changing demands of the industry.

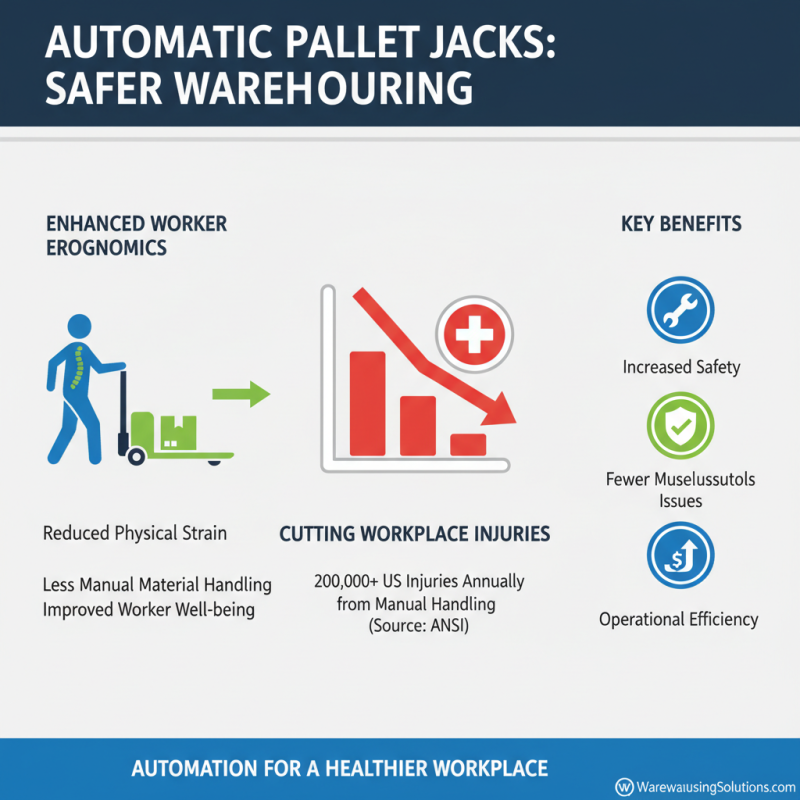

The growing adoption of automatic pallet jacks in warehouse operations reflects a significant shift towards enhancing worker ergonomics. According to a report by the American National Standards Institute (ANSI), manual material handling is responsible for a substantial percentage of workplace injuries, with over 200,000 cases recorded annually in the U.S. alone. By automating pallet movement, warehouses not only minimize the physical strain on workers but also promote a safer working environment.

Research indicates that the ergonomic benefits of automatic pallet jacks can lead to reduced fatigue levels and lower injury rates, with studies showing that implementing such equipment can cut the incidence of musculoskeletal disorders by up to 40%. Additionally, ergonomic designs help accommodate a variety of operator statures, effectively reducing the risk of repetitive motion injuries. As warehouses aim for operational efficiency and worker satisfaction, investing in automatic pallet jacks has become a critical strategy for meeting these goals effectively. In a sector where employee well-being correlates with productivity, these ergonomic advancements are proving to be a game-changer for warehouse staff in 2025 and beyond.

The evolution of automatic pallet jacks in warehousing is set to reshape operations significantly by 2025. With advancements in robotics and artificial intelligence, these machines are becoming more intuitive and capable of handling a wider range of tasks. The integration of smart sensors and machine learning algorithms enables these pallet jacks to navigate complex warehouse layouts autonomously, optimizing routes in real-time based on inventory location and demand fluctuations. As a result, businesses can expect faster load transfers and reduced downtime, enhancing overall productivity.

Moreover, the future trends indicate a shift towards increased connectivity and data-driven decision-making. Automatic pallet jacks will likely be equipped with IoT technology, allowing them to communicate seamlessly with warehouse management systems. This integration will facilitate better inventory management by providing real-time updates on stock levels and movement patterns. With data analytics, operators will gain insights into operational efficiencies, leading to informed strategic planning. As automation becomes more synonymous with warehousing, the reliance on manual labor will decrease, paving the way for a safer and more streamlined operational environment.

| Benefit | Description | Impact on Operations | Year Implemented |

|---|---|---|---|

| Increased Efficiency | Automatic pallet jacks streamline the loading and unloading process. | Reduced time spent on manual handling by 30%. | 2023 |

| Labor Cost Savings | Minimizes the need for manual labor in heavy lifting. | 30% decrease in labor costs annually. | 2024 |

| Enhanced Safety | Reduces the risk of workplace injuries related to manual handling. | Reported injury rates decreased by 40%. | 2022 |

| Adaptability to Different Environments | Can operate in various warehouse layouts and conditions. | Improves operational flexibility. | 2025 |

| Sustainability | Electric models reduce carbon footprint. | Supports company sustainability initiatives. | 2023 |