Leave Your Message

In today’s fast-paced warehouse environment, efficiency is paramount. One way to enhance operational workflow is by utilizing a Pallet Jack Automatic. These machines streamline the handling of goods, allowing employees to focus on essential tasks rather than manual lifting. The automatic features reduce physical strain and increase productivity.

Implementing a Pallet Jack Automatic can transform a chaotic warehouse into a more organized space. With easy maneuverability, these jacks navigate tight areas where traditional forklifts might struggle. Additionally, they can handle heavier loads, which minimizes the time spent on each task. However, the initial investment may cause hesitation for some businesses.

While many companies benefit from this technology, not all employees may adapt quickly. There can be a learning curve associated with the switch. It’s vital for businesses to invest in proper training. This ensures everyone can use the Pallet Jack Automatic safely and effectively. Embracing this change is essential for long-term efficiency.

An automatic pallet jack can transform your warehouse operations. It simplifies the movement of heavy loads and improves efficiency. Using this equipment minimizes the physical strain on workers. Employees can focus on other important tasks instead of constantly moving pallets.

One key benefit is speed. With an automatic pallet jack, loads are lifted and transported much faster than with manual options. This can lead to shorter wait times for shipments. Additionally, operators can maneuver easily in tight spaces. However, it's crucial to regularly maintain the equipment to avoid malfunctions.

Safety is another significant factor. Automatic pallet jacks reduce the risk of workplace injuries. Workers are less likely to strain their backs or drop heavy items. Yet, improper training can lead to accidents. Investing time in training employees on operational techniques is vital for maximizing benefits. Understanding potential risks is equally important in fostering a safe working environment.

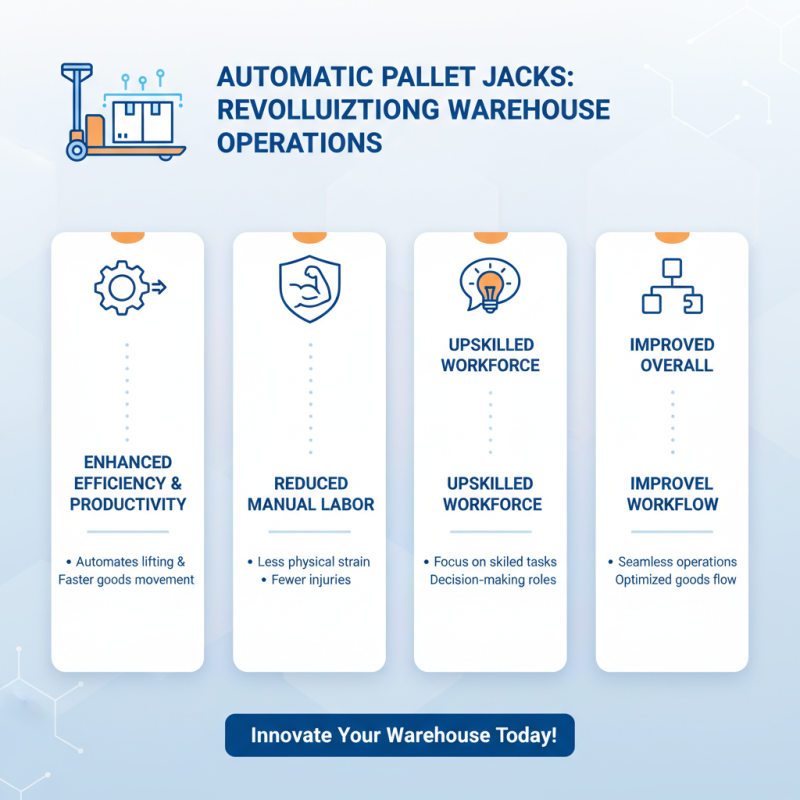

Automatic pallet jacks are revolutionizing warehouse operations. They enhance efficiency and productivity like never before. By automating the lifting and transporting of goods, they reduce manual labor. Workers can focus on tasks that require more skill and judgment. This leads to improved overall workflow.

These machines are designed for ease of use. Operators can maneuver heavy loads without straining their bodies. However, not all employees may adapt quickly to this technology. Training is essential for maximizing the benefits. It's crucial to monitor the transition to avoid potential mishaps. Some employees might find the automatic features intimidating at first.

Moreover, the initial investment can be higher than manual options. It's important to evaluate the long-term savings. Improving efficiency might take time and adjustments. Regular maintenance is also necessary to keep the machines running smoothly. Despite these challenges, the potential for increased productivity is significant. Embracing this technology can lead to a more streamlined operation.

Automatic pallet jacks have become essential in modern warehouses. Their safety features set them apart from traditional models. These enhancements significantly reduce the risk of accidents. Operators benefit from user-friendly controls that allow for precise maneuvering. Visibility is improved, with clear sight lines ensuring safer operation in crowded spaces.

A key safety feature is the automatic stopping system. If an obstacle is detected, the pallet jack halts immediately. This can prevent injuries and equipment damage. Moreover, many models include ergonomic designs that reduce strain on the operator. Users can feel more comfortable during long shifts.

Despite their advantages, challenges remain. Some operators might struggle with the learning curve associated with new technology. Proper training and regular maintenance are essential. Without these, the benefits of automatic pallet jacks can diminish. It’s crucial to monitor performance regularly and address any safety concerns promptly.

When considering warehouse efficiency,

automatic pallet jacks

offer an attractive cost-effective solution. These machines reduce

manual labor, cutting down on employee fatigue.

Workers can move heavy pallets without physical strain. This efficiency translates to

fewer workplace injuries and lower health costs. However, some warehouses may worry about

high initial investments.

While automatic pallet jacks may seem pricey upfront, they can dramatically lower

operational costs over time. Businesses save on labor costs since fewer employees are

needed for moving goods. Moreover, the increased speed of automatic jacks means more

pallets get moved in less time. This can enhance order fulfillment rates, increasing overall productivity.

Yet, it's essential to assess whether the volume of goods justifies such an investment.

Some teams may find it challenging to adapt to new technology. Training staff may take

time and resources. Additionally, if the machinery breaks down, repair costs could add

up quickly. Regular maintenance is vital, yet it can be overlooked during busy periods.

It's crucial to weigh these potential setbacks against the long-term benefits of

efficiency and cost savings. The decision is not always clear,

emphasizing the importance of careful analysis.

In any warehouse, choosing the right pallet jack can significantly impact efficiency. Manual pallet jacks require physical strength and precision. Operators must pump the handle to lift and maneuver loads. This can lead to fatigue, especially during peak hours.

Automatic pallet jacks, however, ease the strain. They lift and maneuver with minimal effort. This distinction can save time and enhance productivity.

Tips: Consider the weight of the loads you typically handle. If they're heavy, an automatic model may be more suitable. Additionally, think about your workforce. If you have many employees rotating through, automatic jacks can help each one perform better with less strain.

Another point to reflect on is the training required. Manual jacks are easier to learn. But, automatic models can reduce the learning curve. There is a trade-off. While automatic jacks are efficient, they can require maintenance. Neglecting this can lead to downtimes. Keep an eye on routine checks and repairs for continuous smooth operation.