Leave Your Message

Choosing the right equipment for your warehouse operations is crucial for maximizing efficiency and safety. One of the most versatile and beneficial tools available is the Rideable Pallet Jack. This innovative piece of machinery not only streamlines the process of transporting pallets but also enhances productivity by allowing operators to ride atop the unit, reducing fatigue during long shifts. However, with various models and features on the market, selecting the best Rideable Pallet Jack to meet your specific warehouse needs can be a daunting task.

In this guide, we will explore key factors to consider when evaluating different Rideable Pallet Jacks, including weight capacity, maneuverability, and battery life. Understanding these aspects will empower you to make informed decisions that align with your operational requirements. Additionally, we will discuss the advantages of integrating a Rideable Pallet Jack into your workflow, ensuring you can efficiently manage heavy loads and navigate tight aisles with ease. By the end of this overview, you'll be well-equipped to choose the optimal Rideable Pallet Jack that will enhance your warehouse's efficiency and streamline your material handling processes.

Understanding the Basics of Rideable Pallet Jacks

Rideable pallet jacks are essential tools for modern warehouses, designed to streamline material handling and improve efficiency. Unlike manual pallet jacks, rideable models allow operators to sit or stand while driving the vehicle, significantly reducing physical strain during long shifts. These machines come equipped with various features that enhance safety and usability, including ergonomic controls, speed adjustments, and tighter turning radii, which are vital for maneuvering in crowded spaces.

Choosing the right rideable pallet jack begins with understanding its key components. The lifting mechanism, typically hydraulic, is crucial for ease of raising and lowering loads, while the weight capacity directly affects operational capabilities. Battery life and charging times are also important considerations, as they influence how long the jack can be used without downtime.

Additionally, selecting the right type of wheels based on the flooring of your warehouse can enhance performance, offering better traction and reduced wear on the machine. By grasping these fundamentals, warehouse managers can make informed decisions that best suit their operational needs.

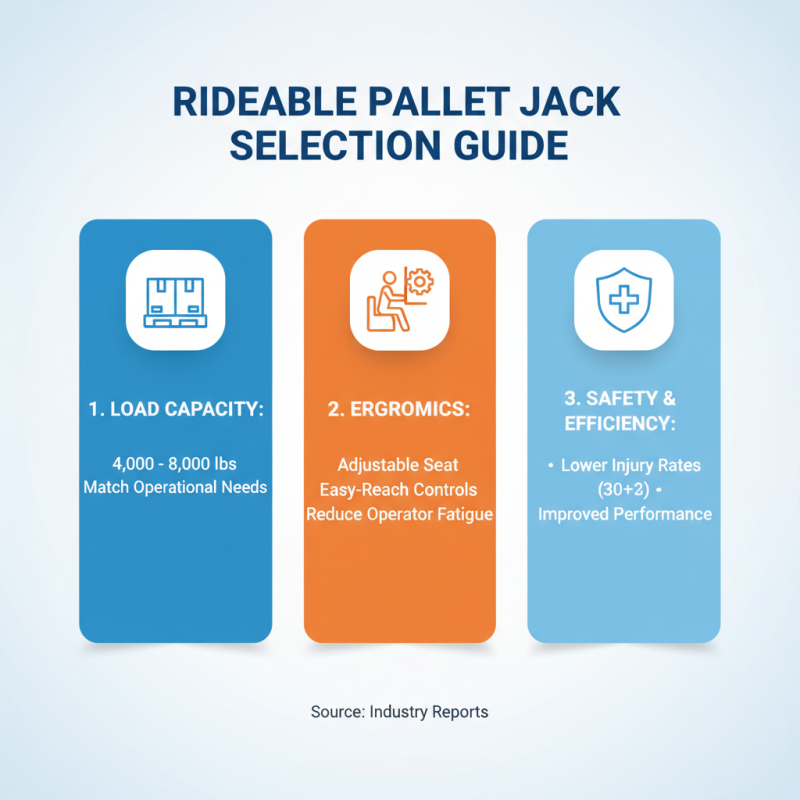

When selecting the best rideable pallet jack for your warehouse, it’s essential to focus on key features that enhance efficiency and safety. First, consider the load capacity; most rideable pallet jacks can handle loads ranging from 4,000 to 8,000 pounds. Analyzing your operational needs will help you choose a model that meets your daily usage without compromising on performance. Additionally, look for models with ergonomic design features, such as adjustable seats and easy-to-reach controls, which are vital for reducing operator fatigue during extended use. According to industry reports, warehouses with ergonomic equipment reduce injury rates by over 30%, highlighting the importance of comfortable machinery.

Another crucial aspect to consider is battery life and charging capabilities. Many modern rideable pallet jacks have lithium-ion batteries that offer faster charging times and longer life cycles compared to older models. For instance, a survey conducted by the Industrial Truck Association noted that 70% of operators prefer equipment that can work an entire shift on a single charge, emphasizing the need for long-lasting battery performance.

**Tips:** When evaluating different models, test their maneuverability in your warehouse layout to ensure they fit your space requirements. Also, consider additional safety features, such as anti-collision sensors and emergency stop functions, which can significantly enhance workplace safety. Investing in a rideable pallet jack with advanced safety features not only protects your workforce but also minimizes potential downtime and liabilities linked to accidents.

When selecting the best rideable pallet jack for your warehouse needs, it’s vital to start by assessing your warehouse space and load requirements. Understanding the dimensions of your aisles and storage areas will help determine the size and maneuverability needed for a pallet jack. A compact model may be ideal for narrow spaces, while a larger unit can handle increased loads more efficiently in spacious environments.

Tips: Measure the width of your aisles and the height of your storage racks to ensure the chosen pallet jack fits comfortably in your space. Consider the turning radius; a smaller turning radius allows for easier maneuvering in tight spots.

Load requirements are equally important. Evaluate the maximum weight you typically handle and choose a pallet jack designed to meet or exceed this weight capacity. Additionally, consider the types of loads you'll be transporting, as varying loads may require different fork dimensions and height adjustments.

Tips: Regularly assess your load needs, as fluctuating inventory can change your requirements over time. This evaluation can help inform future equipment upgrades or adjustments to ensure operational efficiency.

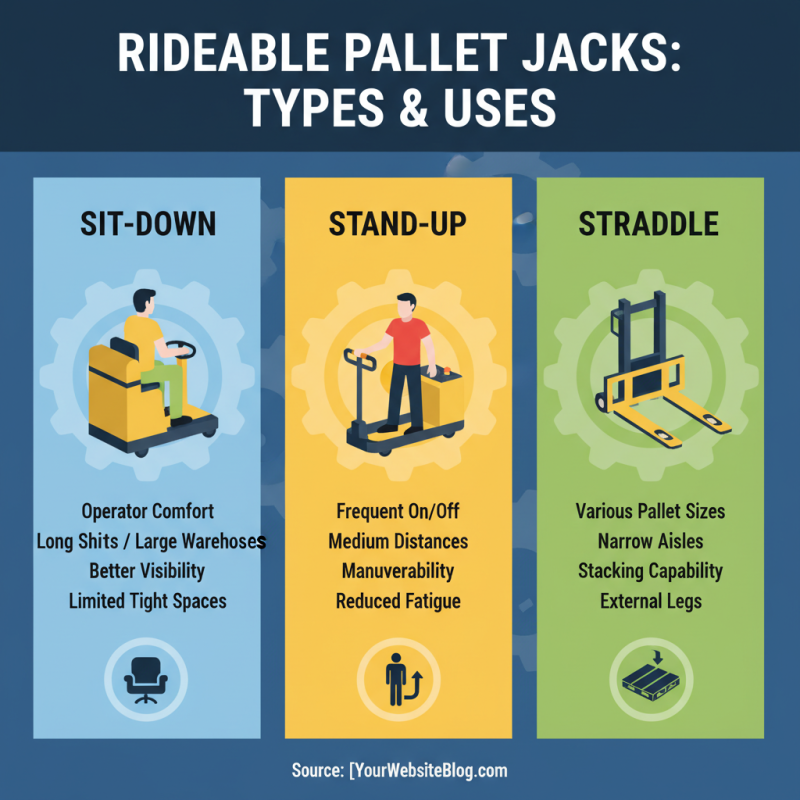

When selecting a rideable pallet jack for warehouse operations, it's essential to understand the differences among the various types available. The most common types include sit-down, stand-up, and straddle pallet jacks. Sit-down models are designed for operator comfort, allowing the user to remain seated while maneuvering, which is ideal for longer shifts or large warehouses where extensive travel is needed. They typically offer better visibility and ease of use, but may have limitations in tight spaces.

On the other hand, stand-up pallet jacks provide a more compact option, giving operators the ability to stand while navigating through narrow aisles. These models are perfect for environments where agility is crucial, as they allow for quick turns and easier handling of pallets in confined areas. Finally, straddle pallet jacks are notable for their ability to handle multiple pallet sizes and are especially useful for lifting pallets that are not standard-sized. Understanding these distinctions can significantly affect the efficiency and productivity of your warehouse operations.

When selecting a rideable pallet jack, it's crucial to consider the maintenance and support options available. Regular maintenance is essential to ensure the longevity and reliability of your equipment. A proactive maintenance schedule will help identify and address potential issues before they escalate, minimizing downtime and repair costs. It's important to verify the availability of service parts locally and ensure that your suppliers provide comprehensive maintenance support as needed.

Tips: Opt for pallet jacks that come with a solid warranty and service package. This can save you money in the long run by covering unexpected repairs. Additionally, consider equipment that features user-friendly diagnostic tools, allowing operators to quickly identify problems and communicate them to your maintenance team effectively.

Moreover, assess the training and support options provided by the supplier. Ensuring that your team is well-trained in the operation and care of the pallet jack will contribute significantly to its maintenance and optimal performance. Look for suppliers who offer training sessions or comprehensive manuals that can help staff troubleshoot common issues independently. Investing in regular training can lead to a more efficient operation and extend the lifespan of your equipment.

| Pallet Jack Type | Load Capacity (lbs) | Battery Type | Charging Time (hours) | Maintenance Frequency (months) | Warranty Period (years) | Support Options |

|---|---|---|---|---|---|---|

| Electric Rideable | 5000 | Lithium-ion | 2 | 12 | 3 | Online & On-site |

| Manual Rideable | 3500 | N/A | N/A | 6 | 1 | Phone Support |

| Semi-Electric Rideable | 4000 | Lead-acid | 4 | 9 | 2 | Online Chat & On-site |