Leave Your Message

When selecting the right Standing Pallet Jack, considerations abound. Industry expert John Smith once stated, "Understanding your specific needs is crucial for optimal performance." His insight emphasizes the importance of matching the equipment to your tasks. A Standing Pallet Jack can significantly boost efficiency in a warehouse or retail setting.

Choosing the best model involves analyzing capacity, maneuverability, and ergonomic features. You need a design that fits your workspace. A well-chosen Standing Pallet Jack not only enhances productivity but also ensures safety. However, many overlook weight capacity. Choosing an inadequate model can lead to accidents and delays.

Additionally, assessing the training required for operators is vital. Misuse can lead to injuries and damage. It’s essential to engage with staff to understand their needs. In the end, every choice should reflect a balance between efficiency and safety. The right Standing Pallet Jack is a reflection of careful thought and practical decision-making.

Choosing the right pallet jack is crucial for efficient warehouse operations. One of the key factors to consider is load capacity. Different pallet jacks have varying weight limits. Misjudging your needs can lead to issues. For example, using a jack with a lower capacity can result in damage to the jack or your goods.

It's important to assess your load requirements accurately. Consider the heaviest pallets you'll handle. Are they consistently heavy, or do you have a mix? If you regularly lift heavy loads, opt for a pallet jack with a higher capacity. Sometimes, people overlook this. They choose based on price rather than load needs.

Reflect on the spaces you'll navigate. A narrow aisle with heavy loads poses challenges. Balance is equally important. If a pallet jack doesn't support your load, stability suffers. A jack that tipples easily isn't safe. Weigh your options carefully. A well-suited pallet jack not only makes work easier but also protects your investment.

This chart illustrates the distribution of available standing pallet jacks based on their load capacity. The data reflects the number of pallet jacks classified under different weight capacities, indicating that the 2000 lbs category has the highest availability.

When selecting a standing pallet jack, evaluating the fork length and width is crucial. A standard pallet has dimensions of 48 inches by 40 inches. Choosing the right fork length helps in accommodating various pallet sizes. Longer forks can lift larger loads but may affect maneuverability in tight spaces.

The width of the forks is equally important. A standard width ranges from 20 to 27 inches. Wider forks provide stability, especially under heavy loads. However, they may not fit in narrow aisles effectively. According to industry studies, selecting the optimal fork dimensions can improve efficiency by up to 15%.

Understanding your workspace layout is an essential step. Narrow aisles may benefit from shorter, narrower forks, allowing for easy navigation. A 2022 industry report indicated that 30% of pallet jack users reported operational difficulties due to improper fork size. Negative experiences in these areas show the need for careful consideration when making your choice.

| Fork Length (inches) | Fork Width (inches) | Load Capacity (lbs) | Optimal Use Case |

|---|---|---|---|

| 48 | 27 | 4000 | Standard Warehouse Operations |

| 42 | 22 | 3000 | Narrow Aisle Handling |

| 36 | 22 | 2500 | Retail Environments |

| 48 | 30 | 5500 | Heavy-Duty Applications |

| 60 | 27 | 4000 | Long Loads Transportation |

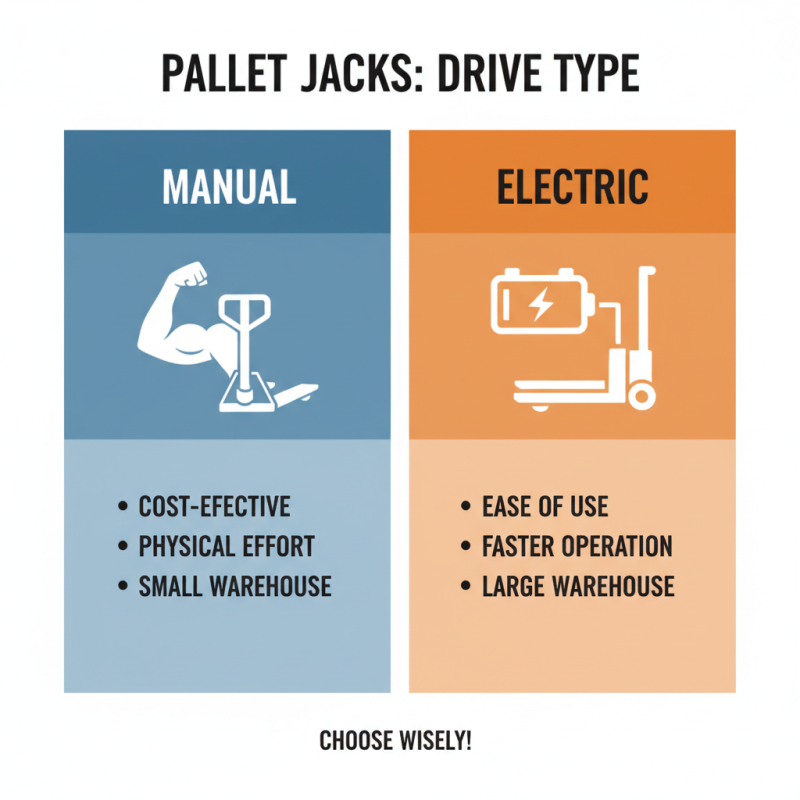

When choosing a pallet jack, assess the drive type. The two main types are manual and electric. Manual pallet jacks are cost-effective. They require physical effort for operation. You must be prepared for the workout. If your warehouse is smaller, they can be a great option. However, they can tire you out quickly.

Electric pallet jacks, on the other hand, offer convenience. They save you energy and improve efficiency. With the push of a button, you can lift heavy loads effortlessly. Yet, they come with a higher price tag and maintenance needs. You must consider battery life too. A dead battery can halt operations.

Think about your specific needs. If you frequently move heavy items, electric may be better. If your jobs are lighter, manual jacks may suit you well. Reflect on these points before deciding. The right choice impacts productivity and worker satisfaction.

When selecting a standing pallet jack, ergonomic features should be a primary concern. Industry reports indicate that nearly 40% of warehouse injuries are related to improper lifting techniques. Ergonomic designs can mitigate these risks significantly. Look for features like cushioned handles and height-adjustable forks. These elements allow operators to maintain a neutral body posture while working.

A survey found that 60% of operators prefer pallet jacks that can be used comfortably for extended periods. Features such as grip-friendly handles can help reduce strain on the hands and arms. Observe how the equipment feels during use. It should enable smooth movement without causing fatigue or discomfort.

Consider the weight capacity and maneuverability as well. However, often overlooked is the jack’s overall weight. A lighter unit can provide better control and ease of use. Yet, it may sacrifice durability. Balancing these factors can be challenging but essential for long-term use. Regular feedback from workers can identify any shortcomings in the ergonomic design. Their insights are invaluable for refining your choice.

When choosing a standing pallet jack, maintenance and warranty options are crucial. Regular upkeep helps prolong the lifespan of the equipment. Simple tasks like checking the wheels and oiling the moving parts ensure smooth operations. Don't ignore signs of wear. A small issue can lead to bigger problems if neglected.

Warranties vary widely. Some manufacturers provide robust coverage for several years, while others offer minimal protection. It’s essential to understand what is included. Look for warranties that cover both parts and labor. Ask questions about what happens if the jack breaks down. A strong warranty can save money in the long run.

Consider how you will use the pallet jack. Frequent use may require more rigorous maintenance. Reflect on whether you have the time and resources for proper upkeep. Choosing a model with easily replaceable parts can simplify maintenance tasks. Finding the right balance between durability and ease of serviceability can be a challenge. Researching options thoroughly pays off in the end.