Leave Your Message

Choosing the right electronic pallet jacks for your business can be daunting. Industry expert John Smith once said, “Selecting the correct equipment can make or break operational efficiency.” This highlights the importance of making informed decisions.

Electronic pallet jacks are essential tools in warehouses and distribution centers. They reduce manual labor and enhance productivity. However, choosing the wrong model can lead to complications. For instance, misunderstanding weight capacities may result in equipment failure.

Not all electronic pallet jacks are created equal. Different businesses have unique needs. For example, a small retailer may require a compact model, while a large warehouse needs heavy-duty options. Consider factors such as lifting height and battery life. A well-considered choice can improve daily operations tremendously.

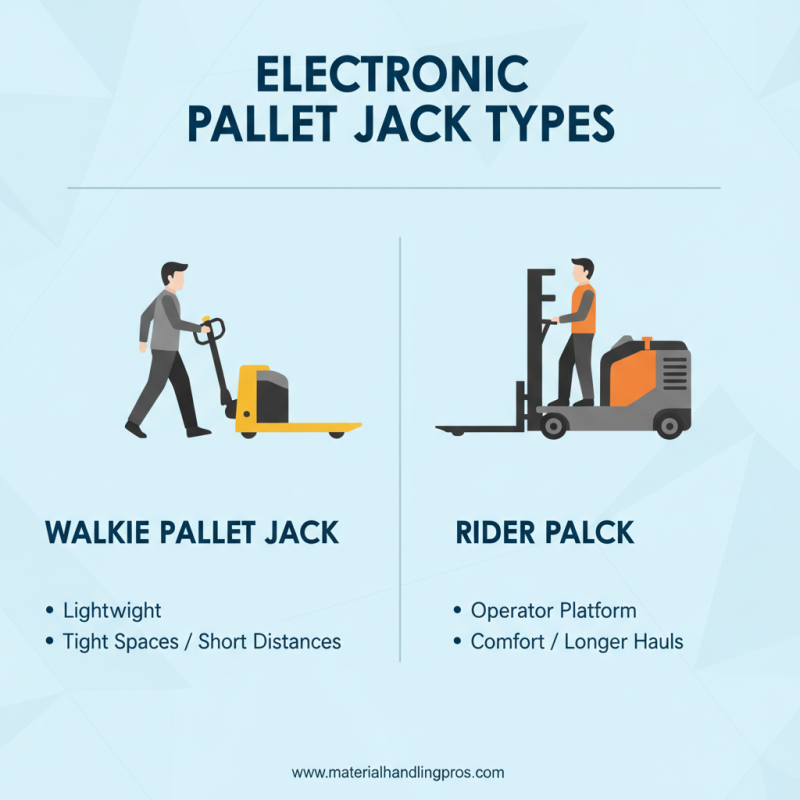

When choosing an electronic pallet jack, it's essential to understand the different types available. Available options include walkie and rider pallet jacks. Walkie pallet jacks are lightweight and great for tight spaces. They are ideal for short distances. Rider pallet jacks offer more comfort for longer hauls. They come with a platform for the operator to stand on.

Consider your warehouse layout. If space is limited, a walkie model might be best. In larger spaces, a rider jack can save time. Pay attention to weight capacity too. Not all models handle the same loads. Utilize the pallet jack for various tasks to find the best fit.

**Tip:** Test multiple models before purchasing. Take note of ease of use. Operator comfort is vital. It impacts efficiency and safety. Listen to feedback from users. Small details can reveal issues. If a jack feels cumbersome, it might not be suitable for your business.

Remember, not every type fits every operation. Analyze your specific needs. Look for equipment that aligns with business goals. Sometimes, investing in multiple types pays off. This ensures flexibility in operations.

When selecting electronic pallet jacks, several key factors come into play. Weight capacity is crucial. Many businesses overlook this. Typical electric jacks handle loads up to 5,500 pounds. However, some operations require more. Not considering weight limits can lead to equipment failure or accidents. The right choice should align with daily operational loads.

Maneuverability is another vital aspect. A wider turning radius can slow down operations in tight spaces. Models with better steering capabilities lead to efficiency, especially in crowded warehouses. Industry surveys show that nearly 30% of pallet jack users face maneuverability challenges. It’s a point that shouldn’t be ignored.

Battery life significantly affects productivity. A jack that can't last a full shift could disrupt operations. Research indicates that 44% of operators experience downtime due to battery issues. Look for models with quick charging capabilities or extendable batteries. Ensuring uninterrupted use is essential in maintaining workflow. Each factor should align with the specific needs of your business.

When selecting electronic pallet jacks, evaluating load capacity is essential. Each model has a specific weight limit. Knowing this limit helps prevent accidents and equipment damage. For instance, a jack rated for 4,500 pounds may not perform well if overloaded. Make sure to assess the heaviest items you handle regularly.

Weight is not the only factor in choosing a pallet jack. Size and maneuverability matter too. A compact model can navigate tight spaces but may have a lower load capacity. Industry needs may change over time, making it essential to revisit your choices. Sometimes, a model that seemed ideal at purchase may fall short under real-world conditions. Listening to the feedback from workers using the equipment can provide valuable insights.

It’s a learning process. Maybe you chose a model for its features, but it’s not suitable for your space. Ensure that your decisions are driven by practical needs rather than just specifications. Balancing load capacity, weight, and intended use is crucial for optimal performance and safety. Consider all aspects before making a final decision.

| Load Capacity (lbs) | Weight (lbs) | Lift Height (in) | Turning Radius (in) | Battery Type | Running Time (Hours) |

|---|---|---|---|---|---|

| 4000 | 550 | 8 | 48 | Lead Acid | 5 |

| 5000 | 600 | 7.5 | 54 | Lithium-Ion | 8 |

| 3000 | 500 | 6 | 42 | Sealed Lead Acid | 4 |

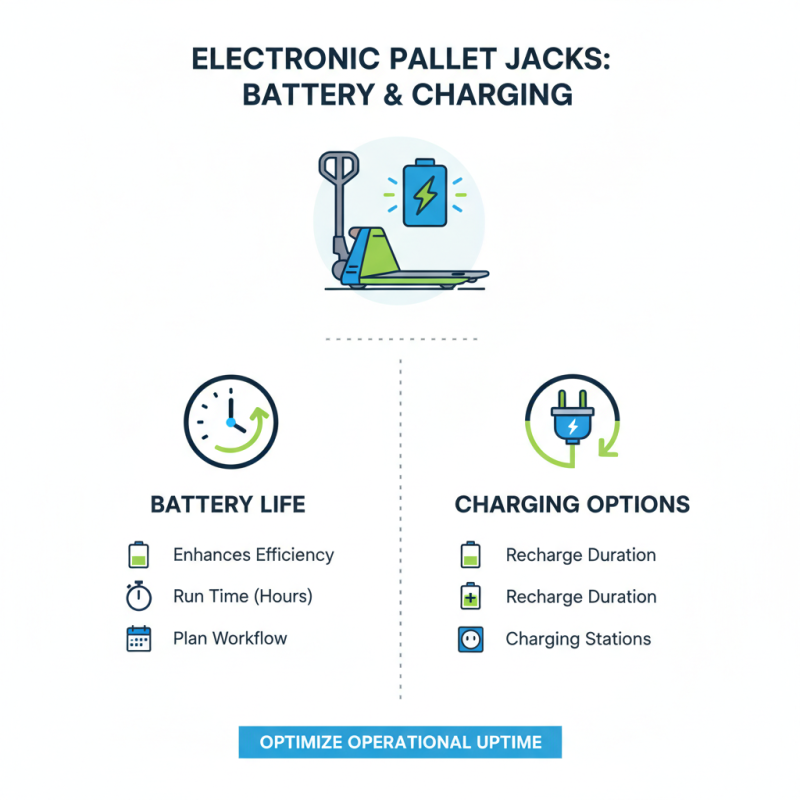

When choosing electronic pallet jacks, battery life and charging options play crucial roles. A strong battery enhances operational efficiency. Ideally, you should assess how many hours the equipment can run before requiring a recharge. Some models may last only a few hours, while others can operate longer. This could impact your workflow if not planned correctly.

Charging options should also be considered. Some pallet jacks come with standard chargers, while others offer faster charging capabilities. Opting for quick-charge features can save valuable time during busy operations. However, it may also lead to decreased battery life if overused. Consider how often the pallet jack will be in use. Frequent usage will require an efficient charging strategy.

Remember, the perfect pallet jack for your needs might not exist. It may require trade-offs. A balance between battery life and charging speed is essential. Reflect on your specific demands and evaluate each option carefully. Each business has unique goals.

When analyzing the cost-effectiveness and ROI of electronic pallet jacks in warehousing, businesses must evaluate several key factors. The initial investment can be significant. However, these jacks often reduce labor costs and improve efficiency. It is crucial to calculate the long-term savings as well.

Tips: Assess your current workflow. Identify any bottlenecks in your operations. This will help you understand potential efficiency gains.

Maintenance costs are another essential aspect. Regular upkeep can prevent costly breakdowns. Businesses should factor these costs into their ROI calculations. Evolving maintenance practices are necessary. Ignoring them might lead to unexpected expenses.

Tips: Consider training staff on proper usage. This can minimize wear and tear. It’s often overlooked but vital for longevity.

Finally, don’t forget to include energy costs. Electric pallet jacks can lead to lower energy bills over time. Still, businesses should compare energy consumption levels. Analyzing data will provide insight into true cost-effectiveness.