Leave Your Message

Choosing the right Heavy Duty Pallet Jack can be challenging. With so many options available, making a decision requires careful thought. A Heavy Duty Pallet Jack is crucial for transporting heavy loads efficiently. It is essential to consider factors such as weight capacity and durability.

When selecting a Heavy Duty Pallet Jack, assess your specific needs. Consider the maximum weight you will handle. Look at the design and material of the jack. A sturdy build can withstand rigorous use over time. Pay attention to the mechanics as well. The ease of maneuvering must not be overlooked.

An ideal Heavy Duty Pallet Jack should meet all operational requirements. Do not rush the selection process, as choosing the wrong model can lead to inefficiencies. Reflect on past experiences with equipment to guide your decision. A thoughtful choice enhances productivity and safety in your workspace.

When selecting the right heavy-duty pallet jack, understanding the various types available is crucial. Heavy-duty pallet jacks come in many models, each designed for specific tasks. There are manual options requiring physical effort, and electric ones for ease. The choice often depends on your operational needs.

Consider the weight capacity. Some jacks can handle over 5,000 pounds, while others may only support 3,000 pounds. The lifting height is another factor. If you need to reach high racks, a longer reach jack may be necessary. Additionally, the wheel type affects maneuverability. Solid wheels work well on smooth surfaces, while pneumatic wheels are better for outdoor use.

Reflect on the environment too. An ideal pallet jack for one setting may not suit another. A jack that works seamlessly indoors may struggle on rough terrain. Think about storage space as well. A larger pallet jack might be difficult to store. The right choice requires careful consideration of many factors, not just price. Assess your needs before making a decision.

When selecting a heavy-duty pallet jack, assessing load capacity is crucial. Each model has a specified weight limit. Exceeding this can lead to accidents. Always check the manufacturer’s guidelines. This information can help determine safe operational limits. Overloading may cause the wheels to buckle or the hydraulic system to fail.

Weight distribution is equally important. An unbalanced load can make maneuvering difficult. It can also lead to tipping hazards. Ensure that loads are evenly distributed across the pallet. Use straps or other securing methods as needed. A load that shifts can lead to mishaps during transport. Trust your instincts; if something feels off, reassess your setup.

The ideal pallet jack should feel stable while moving. Pay attention to how it handles under different loads. Test it on various surfaces to gauge performance. If it doesn't meet your expectations, consider other options. Remember, finding the right balance is not just about capacity; it’s about safety.

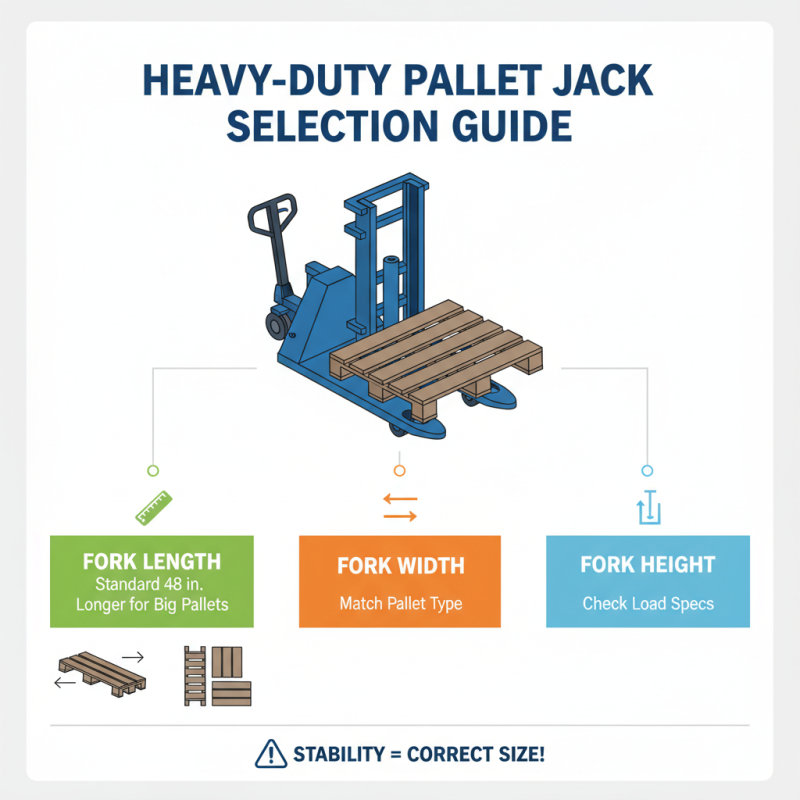

When selecting a heavy-duty pallet jack, fork length, width, and height are essential. Fork length is crucial for handling various pallet sizes. A standard fork length of 48 inches works well, but longer forks help with larger pallets. A mismatch in size may cause stability issues. Check your load specifications.

Fork width affects maneuverability. A narrower width suits tight spaces. However, wider forks provide better weight distribution. Consider how you navigate through aisles. An awkward fit might lead to damaged goods or slow operations. Aim for balance, as both extremes can be problematic.

Height is another consideration. The maximum lifting height must align with your storage needs. If you store items high up, you need a jack that can reach those levels. A low height may lead to strain, while excessive height can be cumbersome. Finding the right fit requires careful assessment. Reflect on your specific situations, as this will guide your choice effectively.

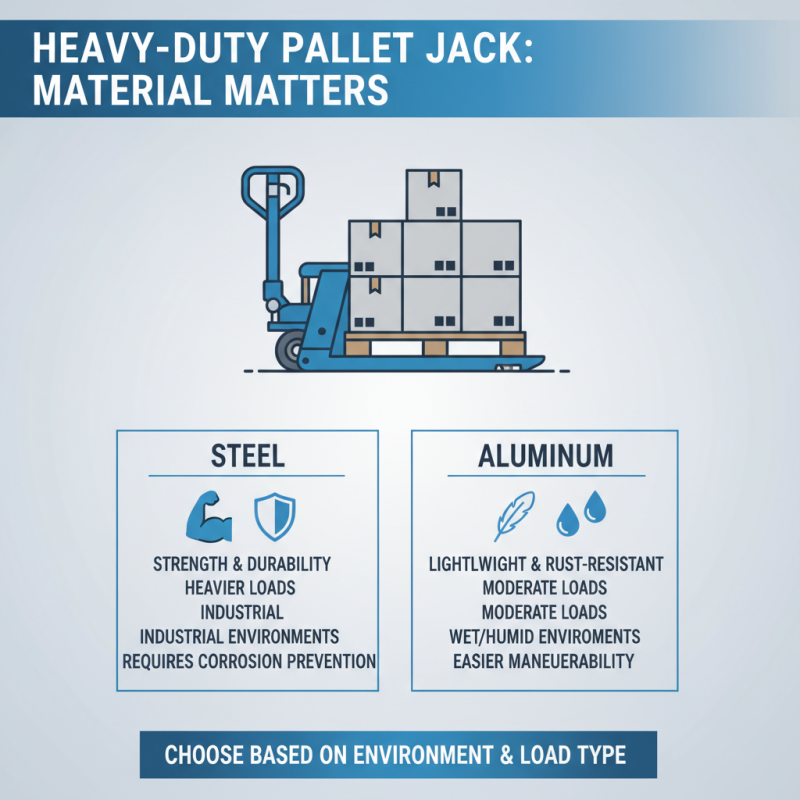

When selecting a heavy-duty pallet jack, the material durability and maintenance requirements are crucial factors. Steel and aluminum are common materials. Steel provides strength, while aluminum is lighter and rust-resistant. The choice depends on your environment and load needs.

Regular maintenance is often overlooked. It’s important to inspect the pallet jack frequently. Check for rust, wear, and tear. Neglecting minor issues can lead to larger problems. Lubricate moving parts to ensure smooth operation. A well-maintained jack lasts longer and is safer to use.

Consider the frequency of use. Heavy-duty jacks might require more rigorous maintenance schedules. Reflect on your environment. Dust and moisture can impact performance. Choose a model that suits your specific needs, but remember to prioritize care and upkeep to maximize longevity. Make a plan, and stick to it.

When investing in a heavy-duty pallet jack, cost and performance go hand in hand. You need to analyze what you are really getting for your money. A higher price tag does not always guarantee superior quality or performance. Sometimes, lower-cost options can be surprisingly effective. Consider the weight capacity you truly need. A jack meant for lighter loads may suffice, even if you occasionally handle heavier items.

Performance isn't just about lifting ability. Look into the ease of maneuverability and overall build. A well-designed pallet jack should glide smoothly on your warehouse floor. Check for features like ergonomic handles. These can reduce operator fatigue during long shifts. However, it’s essential to evaluate the durability of materials used. Not all jacks endure heavy use equally well.

Your workplace environment affects your choice. A jack used on uneven surfaces may need reinforced construction. Conversely, a smooth floor allows for more flexibility in design. Pay attention to the warranty offered. It reflects the manufacturer's confidence and can save costs in the long run. In the end, exploring various options while being mindful of performance and cost is key to making the right investment.

This chart illustrates the cost and performance metrics of various heavy-duty pallet jacks. The data reflects average price and weight capacity, allowing users to make informed decisions based on their needs.