Leave Your Message

Choosing the right pallet jack is pivotal for efficiency in material handling. According to a 2023 industry report by Material Handling Institute, pallet jacks are essential tools in warehouses, influencing productivity levels. They account for over 30% of tasks involving moving goods.

There are various types of pallet jacks available. Manual, electric, and heavy-duty models each serve distinct purposes. A study noted that the right choice can enhance workflow by 25%. Yet, many businesses make decisions solely based on price. This can lead to operational challenges and increased costs over time.

Understanding specific operational needs is critical. A poorly chosen pallet jack can hamper productivity. For instance, using a manual jack for heavy loads may cause strain and delays. Observations show that selecting the wrong design leads to more frequent breakdowns. It's a significant issue worth addressing for long-term viability.

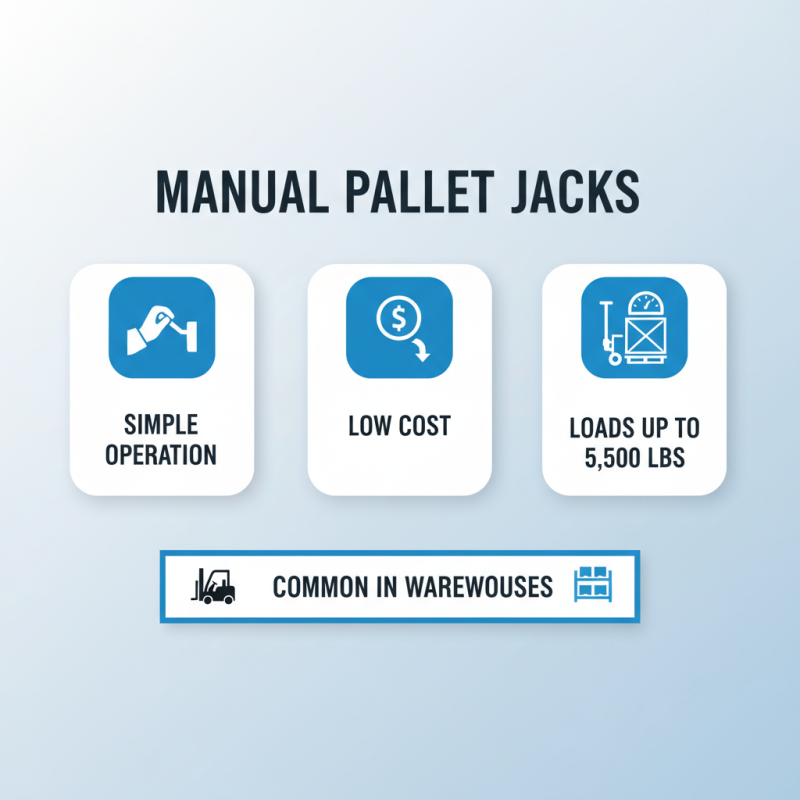

When choosing a pallet jack, it's crucial to understand the types available. Manual pallet jacks are common in warehouses. They offer simple operation and low cost. These models can handle loads up to 5,500 pounds, making them suitable for various tasks.

Electric pallet jacks are another option. They speed up the loading and unloading process. Many electric versions carry up to 6,000 pounds. The battery life typically lasts for a shift but may need charging during the day. Data shows that electric jacks improve efficiency by 30% in busy environments.

Rider pallet jacks are designed for larger operations. Operators can ride on them for longer distances. These jacks benefit businesses that manage more extensive warehouse systems. However, their initial cost is higher. Sometimes businesses underestimate maintenance needs. Proper training is essential to avoid potential accidents. Consider your specific needs before purchasing.

When selecting a pallet jack, understanding your load capacity is crucial. It's easy to underestimate this factor. Consider the weight of the goods you handle daily. A good rule of thumb is to calculate the average weight and add a margin for safety. This ensures you don’t face unexpected challenges. For instance, if your merchandise typically weighs 1,000 pounds, choose a jack with a capacity above that.

Different types of pallet jacks cater to various capacities. Manual jacks are typically heavier and more robust. Electric models often handle more weight but require charging. Think about how often you'll use the jack. Frequent use could lead to faster wear and tear. It's wise to ask yourself if your current operations will expand soon. If that's the case, opting for a jack with a higher capacity may save you future hassles. Balancing your budget with your load requirements can be tricky, but it's essential for long-term efficiency.

When selecting the right pallet jack, size and maneuverability are crucial. A recent study by the Material Handling Industry of America found that 80% of warehouse operational efficiency stems from equipment suitability. Pallet jacks come in various sizes, so understanding your workspace is essential. For narrow aisles, a compact design is necessary. However, larger designs can handle heavy loads effectively, but they may be cumbersome in tight spaces.

Maneuverability is another key factor. Turns and navigation through crowded areas can become problematic. The same study highlights that a well-designed pallet jack can reduce time spent navigating by up to 40%. This statistic emphasizes the need for a jack that aligns with your unique environment. Consider the turning radius and the weight capacity. While a heavier jack may seem appealing, it can hinder movement in small spaces. Hence, finding the balance between size, weight capacity, and maneuverability is essential for enhancing productivity.

Ultimately, the decision should not only focus on load capacity but also on how well the pallet jack can navigate your specific space. Mistakes in this aspect can lead to reduced efficiency, which directly impacts operation costs. Therefore, a thoughtful approach is imperative.

| Pallet Jack Type | Load Capacity (lbs) | Fork Length (in) | Maneuverability Rating (1-5) | Best Use Cases |

|---|---|---|---|---|

| Standard Pallet Jack | 5000 | 48 | 3 | Warehouse operations, loading docks |

| Heavy-Duty Pallet Jack | 8000 | 48 | 2 | Industrial use, heavy materials handling |

| Compact Pallet Jack | 2500 | 36 | 4 | Narrow aisles, small spaces |

| Electric Pallet Jack | 5500 | 48 | 5 | High volume operations, outskirts of warehouse |

| Rider Pallet Jack | 6000 | 48 | 3 | Long distance transport, high throughput |

Choosing the right pallet jack involves considering various factors, particularly ergonomics and operator comfort. According to a study by the Occupational Safety and Health Administration (OSHA), overexertion injuries cost the industry billions annually. These injuries often stem from improper lifting and maneuvering of heavy loads. Prioritizing ergonomics can reduce the risk of injury and enhance efficiency.

When selecting a pallet jack, look for features that boost comfort. Handles with adjustable heights allow operators of various sizes to avoid strain. A cushioned grip can reduce discomfort during extended use. Opt for a model with easy steering mechanisms, as this helps in navigating tight spaces. Data suggests that ergonomic designs can increase productivity by 20% in busy environments.

Tips: Always assess the weight capacity required for your tasks. Heavier loads require more stability. Consider the design of the wheels as well; larger wheels can navigate uneven surfaces. Regular training for operators on proper lifting techniques can make a significant difference in safety. Reflect on the working conditions and employee feedback for continual improvement.

When selecting a pallet jack, durability and maintenance are crucial. A strong, durable pallet jack can handle heavy loads. It should withstand daily use without significant wear. Look for models made from high-quality materials. Steel frames often provide long-lasting support. However, not all steel is the same. Some might rust faster than others in moist environments.

Regular maintenance is vital to ensure longevity. Check wheels and forks frequently for wear. Lubrication is key to keeping the jack functional. Ignoring these tasks may result in costly repairs. Some users overlook noise. Unusual sounds can indicate a problem. It's better to address issues early. Maintenance doesn't have to be extensive. Simple checks can save time and money in the long run.

Re-evaluating your choice over time is wise. What works today may not suit future needs. Observe how the pallet jack performs under different conditions. Can it adapt? Reflect on your experiences. These insights can guide future purchases. Balance durability with ease of maintenance. It’s an essential consideration.