Leave Your Message

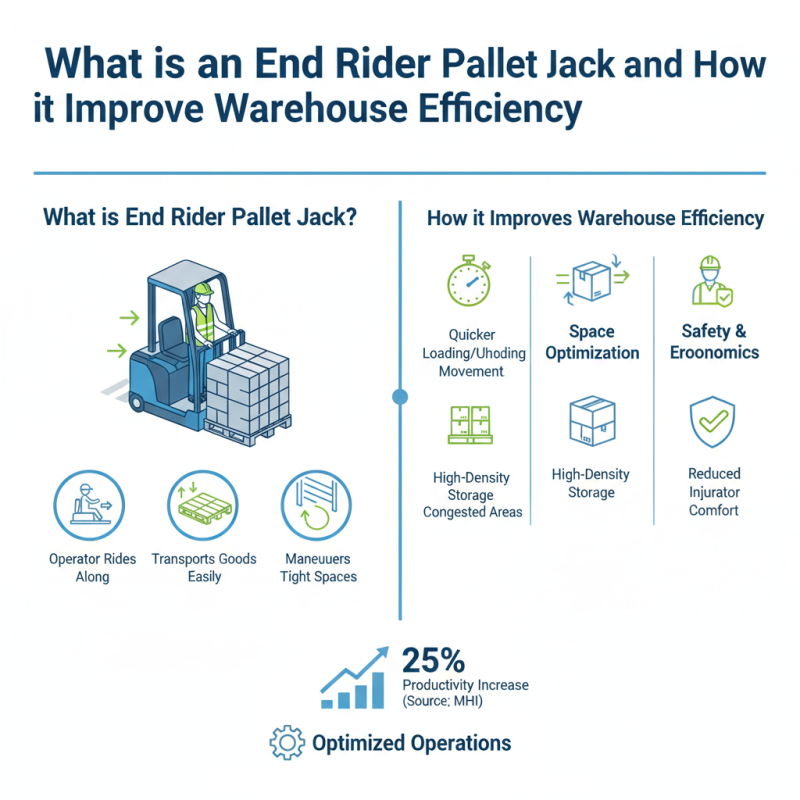

In today's fast-paced logistics environment, warehouse efficiency has become a crucial factor for businesses aiming to stay competitive. One of the innovations that has significantly influenced warehouse operations is the End Rider Pallet Jack. According to a report by the Material Handling Industry of America, effective material handling can improve productivity by as much as 25%, and equipment like the End Rider Pallet Jack plays a pivotal role in achieving this. This type of pallet jack facilitates the easy transport of goods while allowing operators to ride along, enhancing not only speed but also precision in handling materials.

The End Rider Pallet Jack is designed to streamline the movement of goods in congested warehouse spaces. Its unique configuration allows operators to maneuver easily through tight aisles and perform quicker loading and unloading tasks, which is especially vital as warehouses increasingly turn to higher-density storage solutions. Additionally, studies indicate that the implementation of ergonomic equipment, such as the End Rider Pallet Jack, can lead to a notable decrease in workplace injuries, further underscoring the importance of this equipment in promoting both efficiency and safety in warehouse operations. As the demand for faster and more effective logistical solutions grows, understanding the advantages of the End Rider Pallet Jack becomes essential for warehouse managers striving to optimize their operations.

An end rider pallet jack is a specialized piece of equipment designed for the efficient movement of pallets within warehouse operations. This device features a platform that allows the operator to stand at the rear while controlling the jack, increasing mobility and visibility during transportation tasks. The end rider design enables the operator to drive the jack with their body positioned toward the load, allowing for improved balance and comfort while maneuvering through narrow aisles or crowded spaces.

In warehouse operations, what defines an end rider pallet jack is its unique construction that balances power and ease of use. These jacks typically have a higher weight capacity compared to standard manual pallet jacks, making them ideal for moving larger loads across greater distances. Additionally, the ergonomic handle and intuitive controls enhance operator efficiency, reducing fatigue during extended use. Furthermore, end rider pallet jacks are often equipped with advanced safety features such as automatic braking systems and stability enhancements, ensuring safer operations in busy environments. This combination of design elements not only streamlines warehouse processes but also contributes to significant time savings and overall operational effectiveness.

End rider pallet jacks are essential tools designed to enhance warehouse efficiency by optimizing the transport and handling of pallets.

One of their key features is the ability to carry loads at higher speeds compared to traditional pallet jacks, which is pivotal in busy warehouse settings.

According to industry reports, facilities that utilize end rider pallet jacks can see productivity improvements of up to 30%.

This is largely due to their ergonomic design, which minimizes operator fatigue and allows for greater maneuverability in tight spaces.

Another significant advantage is the increased load capacity.

End rider pallet jacks can typically lift heavier loads than standard models, allowing operators to handle more merchandise with fewer trips.

This capability not only decreases the time spent on moving items but also enhances overall throughput within the warehouse.

Additionally, features like adjustable speed controls and enhanced visibility make operating these jacks safer and more efficient, thereby reducing the likelihood of accidents and downtime.

Tip: For optimal performance, operators should undergo proper training to familiarize themselves with the specific features of end rider pallet jacks.

This can significantly reduce errors and increase efficiency during operation.

Incorporating routine maintenance checks into warehouse operations can also prolong the lifespan of these jacks and ensure they remain in peak condition,

thus supporting continuous productivity gains. When equipment is well-maintained, the likelihood of unexpected breakdowns is minimized,

further contributing to a streamlined workflow.

When comparing end rider pallet jacks with traditional pallet jacks, several key differences emerge that highlight their respective advantages in warehouse settings. End rider pallet jacks, designed with an operator platform at the back, allow for enhanced maneuverability and control compared to traditional models that typically require the operator to walk alongside. This design significantly improves productivity by reducing travel time, allowing operators to efficiently move goods over larger distances without unnecessary fatigue.

Additionally, the ergonomic design of the end rider pallet jack caters to both speed and safety, which are crucial in busy warehouse environments. Traditional pallet jacks often necessitate more physical effort to steer and position loads, sometimes leading to slower operations and an increased risk of workplace injuries. In contrast, end rider models provide better visibility and intuitive handling, empowering operators to navigate tight spaces and crowded aisles with ease. This not only streamlines the lifting and transporting process but also enhances overall operational efficiency, making them a preferred choice in modern warehousing practices.

End rider pallet jacks offer significant improvements in warehouse safety standards by enhancing operator visibility and maneuverability. Unlike traditional pallet jacks, end rider models allow operators to ride alongside the load, which minimizes the risk of accidents caused by blind spots when driving. This design not only provides a better view of the surrounding area but also allows operators to react quickly to potential hazards, making the work environment safer for all employees.

Implementing end rider pallet jacks also encourages the use of proper lifting techniques, as operators are less likely to strain themselves when moving goods. By reducing manual lifting and providing greater ergonomic support, these machines contribute to lowering the rate of workplace injuries. This shift not only improves the overall safety of the workplace but also enhances productivity as operators can work more efficiently without the constant worry of injury.

**Tip:** Regular training sessions for warehouse staff on the safe operation of end rider pallet jacks can further bolster safety standards. Ensure that employees are well-versed in how to control the equipment and respond to emergencies.

**Tip:** Incorporate regular maintenance checks on end rider pallet jacks to ensure they are in good working condition. Well-maintained equipment is crucial for preventing accidents and ensuring a smooth operation in the warehouse.

| Feature | Description | Benefits | Impact on Safety |

|---|---|---|---|

| Ergonomic Design | Designed to reduce operator strain with adjustable handle heights. | Enhances comfort during operation, reducing fatigue. | Minimizes risk of injury from prolonged use of poorly designed equipment. |

| Maneuverability | Compact design allows for tight turns and navigation through narrow aisles. | Increases efficiency in storage and retrieval processes. | Reduces risk of collisions in crowded warehouse environments. |

| Speed Control | Includes features to control speed during load handling. | Facilitates faster operation while maintaining control. | Helps prevent accidents caused by excessive speed near workers. |

| Load Capacity | Designed to handle loads up to a specific weight limit. | Maximizes operational efficiency by reducing the number of trips needed. | Ensures safety by supporting loads within specified limits, reducing risk of tipping. |

| Safety Features | Equipped with emergency stop buttons and horn alarms. | Increases safety awareness among operators and nearby personnel. | Directly contributes to prevention of accidents and injuries in the workplace. |

The efficiency of warehouse operations directly impacts the overall cost-effectiveness of supply chain management. Implementing tools like the end rider pallet jack can significantly enhance warehouse efficiency, leading to substantial cost savings. These jacks are designed to easily maneuver around tight spaces, allowing workers to transport goods quickly and efficiently. The reduction in manual labor and the speed at which items can be relocated can streamline operations and minimize delays.

**Tips for Utilizing End Rider Pallet Jacks:**

1. **Training Staff:** Ensure that your staff is adequately trained on how to use the equipment safely and efficiently. This will reduce the risk of accidents and improve overall productivity.

2. **Regular Maintenance:** Keeping the pallet jacks in excellent condition prevents breakdowns that could disrupt warehouse operations. Schedule regular maintenance checks to ensure reliability.

3. **Optimize Layout:** Analyze your warehouse layout to determine how to best utilize end rider pallet jacks. Creating clear pathways can further enhance movement speeds and improve operational flow.

By improving operational efficiency, warehouses can realize significant cost savings, such as decreased labor expenses and lower equipment wear and tear. Tracking performance metrics over time will provide valuable insights into the effectiveness of these improvements, enabling informed decisions for future warehouse strategies.