Leave Your Message

In sectors requiring heavy lifting, the Heavy Duty Pallet Jack stands out. This tool is essential for efficiently transporting goods. Experts like John Smith, a material handling specialist, emphasize its importance: "A Heavy Duty Pallet Jack transforms warehouse operations."

These jacks can handle loads exceeding 5,000 pounds. Their robust design ensures durability, often seen in busy warehouses. However, not all operators know how to utilize them safely. Proper training is crucial to avoid accidents and injuries.

Understanding how a Heavy Duty Pallet Jack works can improve efficiency. While they are straightforward, misusage can lead to equipment damage or harm. Regular maintenance is also necessary but often overlooked. Therefore, awareness is key in leveraging the benefits of this invaluable tool.

A heavy-duty pallet jack is a crucial tool in warehouses and distribution centers. Designed for lifting and transporting heavy loads, it can handle up to several tons with ease. The robust construction ensures durability, even in demanding environments. This equipment is generally used with pallets, making it efficient for moving goods from one place to another.

Using a heavy-duty pallet jack is straightforward. Operators simply insert the forks into the pallet and engage the hydraulic lift system. A hand pump facilitates lifting, while the wheels allow for easy maneuvering. However, the handling requires some skill. Awareness of weight limits and proper loading techniques is essential. Otherwise, it could lead to accidents or damage.

Maintaining a heavy-duty pallet jack also needs attention. Regular checks on the hydraulic system and wheels are important. Neglect can lead to malfunction. This equipment is not infallible; wear and tear happen over time. Identifying issues early can prolong its lifespan and ensure safe operation. Utilizing this tool effectively can enhance workflow but demands respect and understanding of its capabilities.

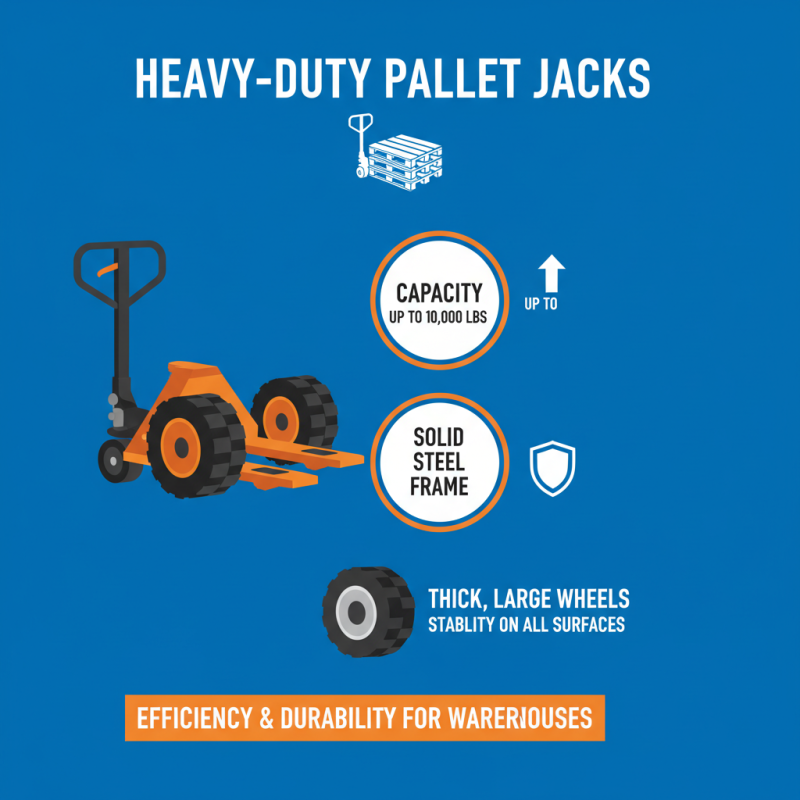

Heavy duty pallet jacks are vital for transporting heavy loads in warehouses. These robust tools can handle weights well beyond standard jacks. Most models feature a solid steel frame that enhances durability. Their large, thick wheels provide stability on various surfaces, making movement smoother.

One key feature is the adjustable forks. They can fit pallets of different sizes, increasing versatility. Rigid steel construction protects against damage. Another important aspect is the ergonomic handle. It allows for easy maneuvering, reducing the risk of operator strain. Users often overlook regular maintenance. Keeping the wheels and forks clean is crucial for optimal performance.

Tips: Always check the weight limits. Overloading can lead to accidents. Utilize the pallet jack on level surfaces when possible. This prevents tipping and enhances safety during transport. Understanding your specific needs is important. A heavy duty pallet jack may not be necessary for lighter loads. Be mindful of your environment to maintain efficiency.

A heavy duty pallet jack is a vital tool for moving large loads. It typically features robust wheels and a strong frame. These jacks are designed for warehouse environments and can handle substantial weight. Loading is streamlined due to their simple yet effective hydraulic design. Operators can lift pallets with minimal effort. Just squeeze the handle to raise the forks. It’s straightforward.

Operating the pallet jack can be tricky, though. It's essential to maintain balance when moving heavy loads. Uneven surfaces can cause the jack to tip over. This may create safety hazards. Using proper lifting techniques is crucial for the operator's safety. Sometimes, the load may shift unexpectedly. This can lead to accidents or damage.

Regular checks of the pallet jack's condition are important. Inspect the wheels for wear and tear. Make sure the hydraulic system functions properly. Neglecting these checks may lead to breakdowns. Operators should be aware of their surroundings while maneuvering. Tight spaces can pose challenges. Reflect on these aspects to improve efficiency and safety.

Heavy duty pallet jacks are essential tools for warehousing operations. They can lift heavy loads efficiently and help in moving items across the facility. These jacks are designed to handle significant weight, often over 5,000 pounds. This capability enhances productivity on the warehouse floor. Workers can transport bulky goods without strain or injury.

Using heavy duty pallet jacks offers numerous benefits. They reduce the risk of back injuries. With better ergonomics, workers can operate them with minimal effort. These jacks also speed up the process of loading and unloading. In busy warehousing environments, time is critical. The faster goods move, the better the overall efficiency.

Tips: Always check the weight limits before use. Overloading can cause accidents. Regular maintenance is crucial, too. Inspect the wheels and hydraulic systems. Neglecting this can lead to unexpected breakdowns. Training employees on safe operation is vital. This reduces errors and enhances safety for everyone.

Maintaining a heavy-duty pallet jack is essential for safe operation. Regular inspections can prevent major issues. Check the wheels for wear and tear. Ensure the hydraulic system is free of leaks. A simple visual check can reveal hidden damage.

Lubrication is crucial for optimal performance. Use appropriate grease on moving parts. It's often neglected, yet it makes a difference. Consider the environment when operating the pallet jack. Dust and debris can cause malfunctions. Clean the equipment regularly to avoid buildup.

Operator training is vital. A poorly trained worker may misuse the pallet jack, leading to accidents. Invest time in teaching proper handling techniques. Make it a habit to report any unusual noises immediately. Delaying can lead to bigger problems down the line. Regular maintenance checks are not just smart; they save money.