Leave Your Message

A Long Fork Pallet Jack is an essential tool in warehouses and retail settings. It functions to lift and transport pallets, allowing for smoother operations. Where space is limited, this tool excels. The longer forks provide an advantage when handling oversized or heavier loads.

Using a Long Fork Pallet Jack requires both skill and attention. Operators must be aware of their surroundings. Maneuvering through tight spaces can be challenging. Safety should always be a priority. Reflecting on past experiences can help improve handling techniques.

One must consider the weight limits and proper loading methods. Overloading the jack may lead to accidents. It's important to keep the load balanced. Understanding the mechanics of a Long Fork Pallet Jack can enhance efficiency. With practice, operators can master its use. Observing others can also provide valuable insights.

A long fork pallet jack is a specialized tool used in warehouses and distribution centers. Its forks are longer than standard models, allowing it to handle oversized pallets. This design makes it invaluable for moving big and bulky items. Workers often find it easier to maneuver heavy loads, especially when space is tight.

Using a long fork pallet jack requires attention to detail. Proper positioning of the forks is crucial for stability. Inexperienced users may struggle to lift pallets evenly. It is important to check the weight limits, as overloading can lead to accidents. Practice helps build confidence, but caution should always be a priority. The operation may feel intuitive, yet even small mistakes can lead to damage or injury.

When navigating tight aisles, awareness is key. Being mindful of surroundings prevents collisions. Slow and steady movements are recommended. Some users may rush and skip important steps, focusing solely on speed. This often leads to complications. Understanding how to use this tool effectively takes time and experience.

Long fork pallet jacks are vital in warehouses and distribution centers. They extend the range of standard pallet jacks, allowing users to handle longer loads effectively. Typically, these jacks feature fork lengths that go beyond the usual 48 inches, which can reach up to 72 inches. According to industry reports, about 25% of warehouses utilize long fork pallet jacks to enhance their operational efficiency.

Key specifications often include a load capacity ranging from 4,500 to 5,500 pounds. This capacity makes them suitable for heavy-duty operations. Many models also have adjustable forks. Operators can adjust the fork width to accommodate various pallet sizes. This flexibility is beneficial in diverse working environments. The minimum turning radius for these jacks is generally around 60 inches. This can pose a challenge in narrower aisles.

Long fork pallet jacks also incorporate safety features. Most have a built-in automatic brake, which activates when the operator releases the handle. However, users must be vigilant. Some operators may overlook proper training, leading to potential accidents. Additionally, while the longer forks offer many advantages, they can also lead to stability issues when handling unbalanced loads. Operators must develop awareness to mitigate these risks effectively. This attention to detail can significantly impact safety and efficiency in material handling.

Long fork pallet jacks are increasingly popular in warehousing. These jacks extend the reach of traditional models. They can handle longer loads effectively. A study from the Warehouse Automation Association reveals that long fork jacks improve load management by 30%. This efficiency boosts productivity significantly.

One major advantage lies in their ability to accommodate larger pallets. Standard pallet jacks struggle with oversized items. Long forks change this dynamic, allowing for better space utilization. Warehouse managers report that these jacks reduce the time spent maneuvering large loads by up to 40%. This improvement is crucial in tight operating environments.

However, not all applications benefit from long fork jacks. Certain narrow aisles may pose challenges. Operators should evaluate their workspace before using these tools. Training is also important. Some workers may find handling longer forks awkward initially. Overall, while they offer significant advantages, careful consideration is essential for effective usage in warehousing.

Operating a long fork pallet jack requires careful attention. Start by ensuring the equipment is in good condition. Check for any loose parts, fluid leaks, or worn tires. A faulty pallet jack can lead to accidents. Statistics show that over 30% of workplace injuries involve material handling equipment. Staying safe is essential.

When using a long fork pallet jack, load distribution matters. Keep the weight centered on the forks. This helps maintain balance while moving. If the load is uneven, it may tip. Avoid quick turns. They can cause the jack to flip. Also, remember to lower the forks when moving. This offers better stability.

Tips for safe operation: Always wear proper footwear. Good traction prevents slips. Practice maneuvering in an open area before engaging in tight spaces. Familiarity with your environment can reduce accidents. Regular training can enhance skills and awareness. Prioritize safety to create a better workplace.

| Feature | Description | Safety Tips | Operating Steps |

|---|---|---|---|

| Fork Length | Longer than standard pallet jacks, typically around 60 to 72 inches. | Always check the load before lifting; ensure it is within weight capacity. | Adjust the forks under the load carefully. |

| Weight Capacity | Typically can hold up to 4000 lbs. | Use proper lifting techniques to avoid injuries. | Engage the hydraulic control to lift the load smoothly. |

| Steering Mechanism | Includes a steering wheel for maneuvering tight spaces. | Keep hands clear of moving parts while steering. | Steer gently to avoid tipping the load. |

| Material | Often made of steel for durability and strength. | Inspect the equipment for any damage before use. | Lower the forks gradually after loading/unloading. |

| Special Features | May include adjustable forks or added weight for stability. | Wear appropriate footwear and gloves while operating. | Follow designated pathways to avoid collisions. |

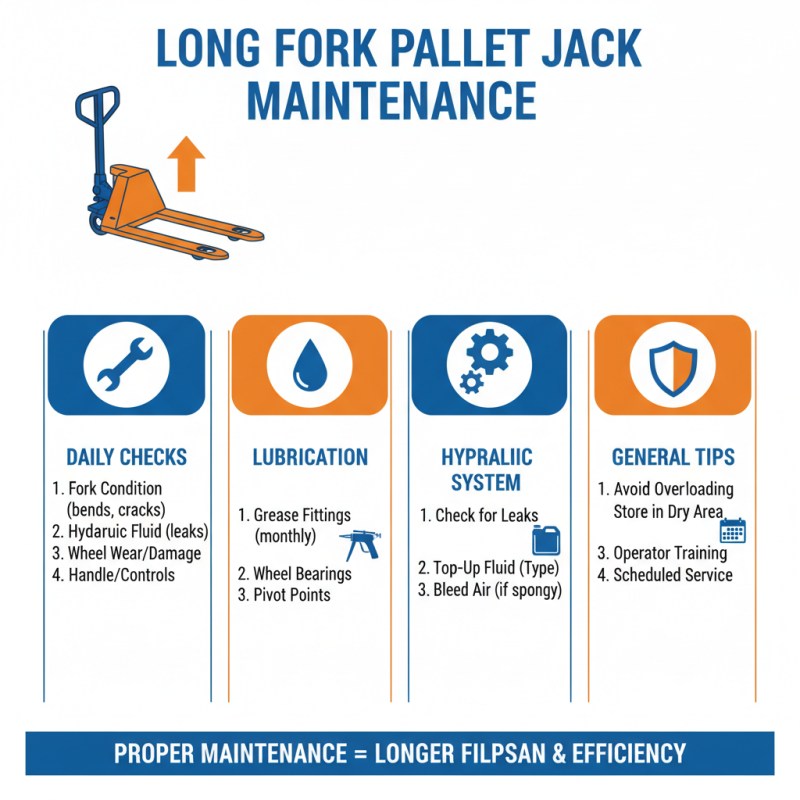

Long fork pallet jacks are essential tools in warehouses and large storage spaces. They allow users to lift and transport heavy loads efficiently. However, to ensure their longevity, proper maintenance is crucial.

Regular inspection is a must. Check the hydraulic system for leaks. Look at the wheels for wear and tear. Tighten all bolts and screws occasionally. It's easy to overlook these small details, but they can lead to larger issues. Keeping the jack clean is vital. Dirt and debris can affect performance. A simple wipe-down after use can go a long way.

Remember to lubricate moving parts regularly. Use the appropriate oils for smooth operation. If the jack becomes noisy, it might need more attention. Don't ignore unusual sounds. Routine maintenance can help prevent costly repairs. It's okay to reflect on forgotten tasks. A few extra minutes can save hours of inefficiency later. Prioritizing these maintenance tips ensures your long fork pallet jack remains reliable for years.