Leave Your Message

In today's fast-paced warehouse environment, efficiency is key. Experts emphasize the importance of choosing the right equipment. John Thompson, a seasoned warehouse operations consultant, states, "A Powered Pallet Jack transforms the way we handle materials." This equipment offers numerous advantages that can streamline operations.

Powered pallet jacks are designed to lift and move heavy loads with ease. They reduce the strain on workers, enhancing safety and productivity. However, it's crucial to consider the specific needs of your warehouse. Not every operation benefits from a powered model. Some may find traditional manual options more suited to their tasks. Evaluating your requirements is essential.

Incorporating powered pallet jacks into your workflow can dramatically improve efficiency. Yet, overspending on features you may never use could be a regret. Understanding how these tools fit into your operations might require reflection and adjustment. Consider the balance between cost and function to make the best choice for your warehouse.

Powered pallet jacks are revolutionizing warehousing operations. According to recent industry reports, these machines can increase productivity by up to 30%. They facilitate quick movement of goods, reducing the time spent on manual labor. Workers can load and unload pallets with ease, minimizing strain and fatigue.

Safety is another significant benefit. Studies indicate that powered pallet jacks reduce workplace injuries by 45%. Operators are less likely to experience back or joint pain when using these machines. However, training is essential. Many accidents occur due to improper operation. Regular safety drills can ensure that employees understand how to use these tools correctly.

Powered pallet jacks also provide efficiency in tight spaces. These machines can maneuver easily in narrow aisles. This flexibility allows warehouses to maximize their storage capacity. However, not all operations may find them suitable. Some facilities may have specific layouts that could limit effectiveness. Reflection on these aspects is crucial for making informed decisions.

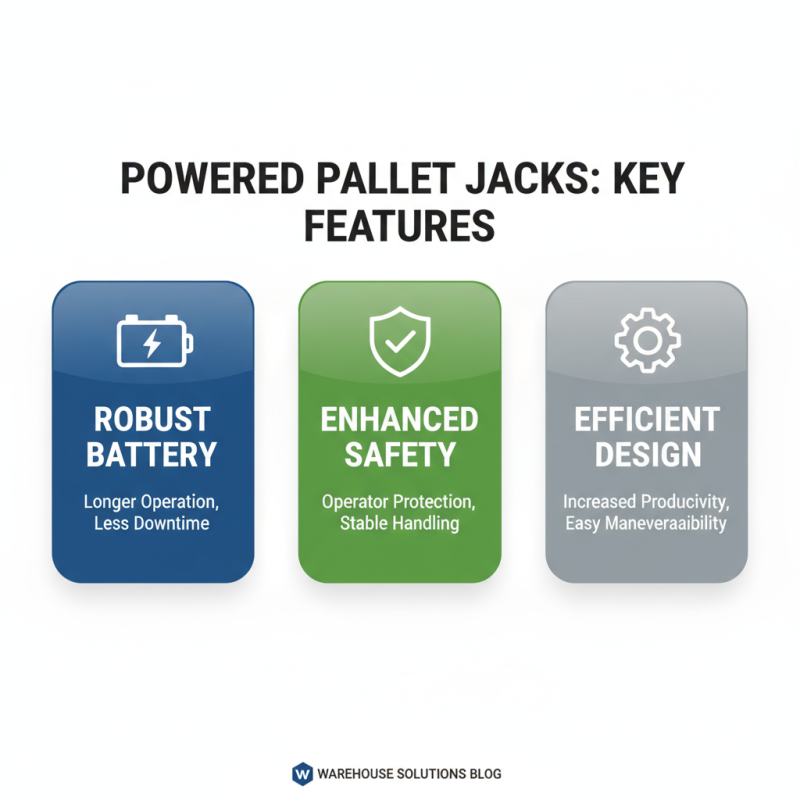

When selecting a powered pallet jack for your warehouse, focus on key features. These jacks are designed for efficiency and safety. Look for models with a robust battery. A strong battery allows for longer operation without frequent recharges.

Consider the weight capacity as well. A jack should handle your typical loads easily. Overloading can lead to mechanical issues. This can be frustrating and costly. Check if the design allows for easy maneuvering. A tight warehouse space demands agility.

**Tips:** Always test the steering before purchasing. Great maneuverability can save time. Think about maintenance, too. Some jacks require more upkeep than others. Read reviews on ease of repair to avoid surprises later.

A powered pallet jack should have a comfortable handle. You might be working long hours. An ergonomic design can reduce strain. Remember, safety features are critical as well. Look for automatic braking systems and emergency stops. Safety should never be an afterthought.

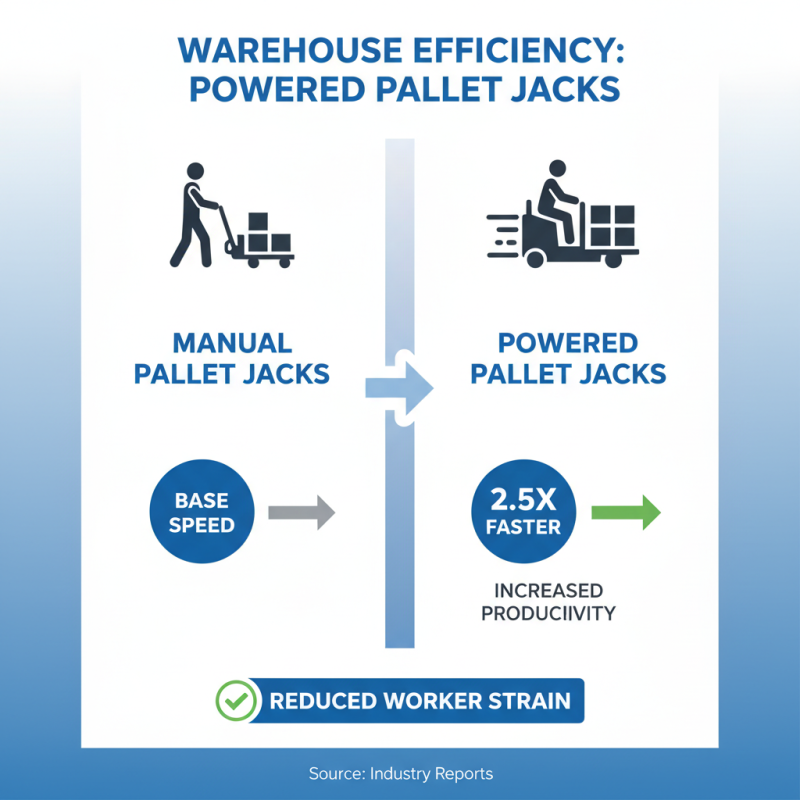

In any warehouse, efficiency is crucial. Powered pallet jacks offer significant advantages over their manual counterparts. According to industry reports, powered models can move loads up to 2.5 times faster than manual jacks. This speed boosts productivity and reduces strain on workers.

Manual pallet jacks require physical effort to operate. Workers must push or pull heavy loads, which can lead to fatigue. Research indicates that physical stress contributes to injuries, accounting for nearly 30% of warehouse accidents. In comparison, powered jacks minimize manual labor, making operations safer.

Battery-operated models have long-lasting power options. Some can run for a full shift without needing a recharge. However, the upfront costs can be high. Investment in powered jacks could lead to better long-term outcomes. But not all businesses may find this financially viable initially. Reflecting on these factors can help in making informed decisions about warehouse equipment.

Powered pallet jacks can greatly enhance efficiency in warehouses. However, safety must remain a priority. According to the Bureau of Labor Statistics, materials handling contributes to over 25% of workplace injuries. Thus, understanding proper use is crucial.

Ensure operators receive adequate training. They should learn about the equipment's controls and safety features. Before each use, check the jack for any damages. Visual inspections can prevent accidents. A study by the Occupational Safety and Health Administration found that regular maintenance reduces injury rates by up to 50%.

Tip: Always wear personal protective equipment while operating. Visibility is key. Keep aisles clear to avoid collisions. Furthermore, keep loads stable and evenly balanced to maintain control.

Regarding visibility, ensure the area is well-lit. Poor visibility increases the risk of accidents. Operators should maintain awareness of their surroundings. Communication with team members is vital. Ignoring this can lead to serious oversights. A recent survey highlighted that over 60% of incidents result from lack of communication.

Tip: Utilize hand signals or two-way radios to ensure safety. Regularly discuss safety practices with your team. This cultivates a culture of safety that can save lives.

When considering warehouse efficiency, powered pallet jacks often emerge as a cost-effective choice. A study from the Material Handling Industry of America revealed that these machines can reduce labor costs by up to 20%. This significant saving often translates to a rapid return on investment, typically within 1-2 years of purchase.

Powered pallet jacks can lift and move heavy loads with ease. This capability minimizes workplace injuries, a costly issue. According to the Occupational Safety and Health Administration, businesses lose over $1 billion annually due to workplace injuries. Using powered pallet jacks can substantially lower these risks and costs.

However, some might worry about the initial investment. While powered pallet jacks have a higher upfront cost than manual versions, their efficiency and safety benefits significantly outweigh this. Many warehouses report improved productivity. Yet, not every facility may need such machinery. Evaluating specific needs and usage frequency before making a purchase is crucial. Decisions should always consider the overall cost-effectiveness and operational requirements.

| Feature | Powered Pallet Jack | Manual Pallet Jack |

|---|---|---|

| Cost | $4,500 - $6,500 | $300 - $800 |

| Operating Cost per Hour | $0.50 | $0.10 |

| Average Lifespan | 10 years | 7 years |

| Load Capacity | 4,000 lbs | 5,500 lbs |

| Return on Investment (ROI) | 2-3 years | Not Applicable |

| Maintenance Costs | $200 annually | $50 annually |