Leave Your Message

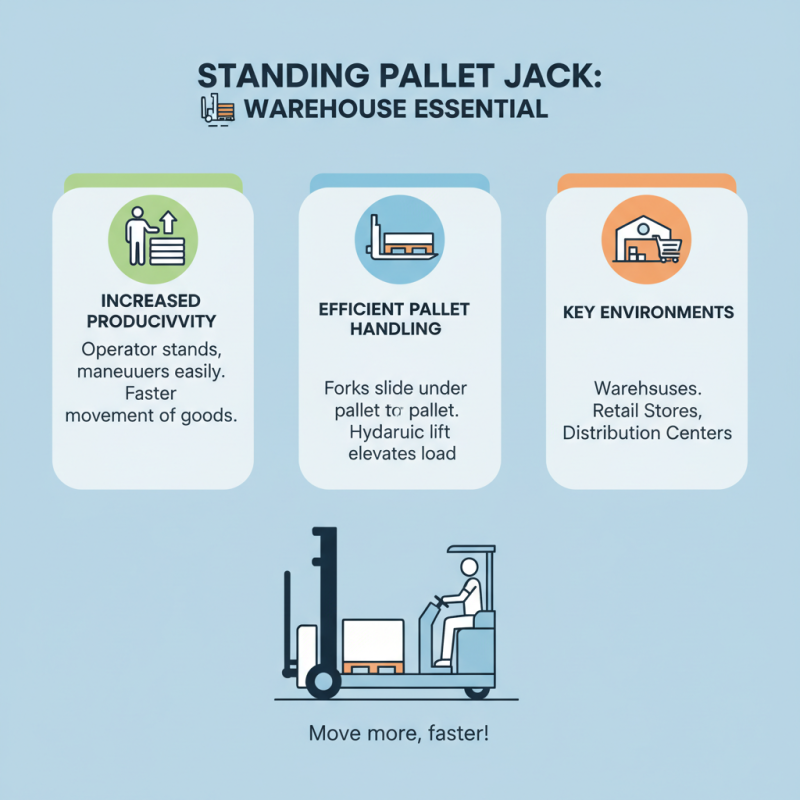

A Standing Pallet Jack is an essential tool in warehouses and distribution centers. It simplifies the movement of palletized goods. With its compact design, it stands upright when not in use. This feature saves space and ensures easy access.

The functionality of a Standing Pallet Jack is straightforward. Operators use a manual lever to lift pallets off the ground. The wheels allow for smooth maneuvering through tight spaces. This is particularly useful in busy environments. However, its simplicity can sometimes lead to oversight, such as not checking the weight limit.

In many ways, the Standing Pallet Jack reflects modern logistics demands. It's efficient but requires careful handling. Neglecting maintenance can lead to malfunctions, affecting productivity. Users must be mindful of their actions to ensure safety. The Standing Pallet Jack, while convenient, demands respect and attention.

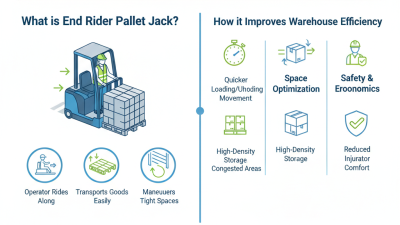

A standing pallet jack is a type of material handling equipment designed for lifting and transporting pallets. Operators find it efficient for navigating tight spaces in warehouses and retail environments. Unlike traditional pallet jacks, standing pallet jacks allow the operator to stand on a platform, providing better visibility and control.

These jacks are often equipped with electronic lifting mechanisms. Research indicates that workplaces utilizing standing pallet jacks can see a reduction in worker fatigue by up to 30%. This reduction is vital in maintaining productivity throughout a shift. Moreover, using these jacks can decrease the risk of injury. In a report by the Occupational Safety and Health Administration (OSHA), improper lifting leads to over 30% of workplace injuries in warehousing.

However, not all workplaces may benefit equally from standing pallet jacks. Some users report difficulty in handling heavier loads, questioning the weight limits of their specific model. Training is essential; untrained operators might face challenges adapting to this equipment. Balancing efficiency with safety should always be a primary consideration in any facility.

This bar chart represents the total units of standing pallet jacks in use across five different warehouses. The data shows the varying levels of usage, offering insights into equipment management and operational efficiency.

Standing pallet jacks are essential tools in warehouse operations. They help transport heavy loads over short distances. Understanding their key components is vital for efficient use.

One main part is the fork. It lifts and supports the pallets during movement. The forks are adjustable, allowing for different pallet sizes. Another important component is the handle. Operators use it to maneuver the jack. A well-designed handle minimizes strain on the user's arms.

The hydraulic system is crucial as well. It powers the lifting mechanism. Regular maintenance is needed here; neglect can lead to performance issues. Wheels also play a significant role. They must be durable and suitable for various surfaces. A weak wheel can hinder movement and cause accidents. Proper selection and care for each component can enhance safety and efficiency.

| Component | Description | Function |

|---|---|---|

| Handle | The part of the jack that the operator grips to maneuver the pallet jack. | Allows user to lift and steer the pallet jack. |

| Forks | The horizontal arms of the jack that slide under the pallet. | Support the pallet load. |

| Lifting Mechanism | Hydraulic system that facilitates lifting of the forks. | Raises and lowers the load. |

| Wheels | The round components that allow the pallet jack to roll. | Enables movement of the jack across surfaces. |

| Brakes | Mechanism that helps to stop the pallet jack. | Ensures stationary stability when loading or unloading. |

A standing pallet jack is a crucial tool in warehouses and retail environments. It allows operators to lift and move pallets efficiently. The design enables the user to remain standing while maneuvering, which increases productivity. These jacks have a simple mechanism, which consists of forks that slide under the pallet. Once in place, the operator uses a hydraulic lift to elevate the load.

To operate a standing pallet jack, the user pushes a lever or presses a button. This action activates the hydraulic system. The forks automatically lift the pallet off the ground. With a well-designed base, stability is maintained, even when transporting heavy items. The controls are generally easy to learn. This allows new users to adapt quickly.

Tip: Always check the weight limit of the jack before use. Overloading can lead to malfunctions or accidents. Additionally, keep the pallet jack’s wheels clean for smoother operation.

However, there's room for improvement. Operators sometimes overlook the importance of proper training. This can lead to misuse, which may cause injuries. Regular maintenance is also often neglected. Worn-out parts can affect functionality. Prioritizing safety and regular checks will enhance efficiency significantly.

A standing pallet jack is a powerful tool in warehouses and retail environments. It allows operators to transport pallets quickly and efficiently. One of the main advantages of using a standing pallet jack is its ergonomic design. Operators can easily maneuver the jack while standing. This reduces physical strain compared to traditional pallet jacks.

Another key benefit is increased productivity. With a standing pallet jack, workers can navigate tight spaces effectively. The compact size allows for easier movement around aisles and stacks. This can lead to faster loading and unloading times. However, it's important to note that inexperienced operators might struggle initially. Proper training is essential for maximizing efficiency.

Safety is also a significant advantage. Many standing pallet jacks come with safety features, such as automatic braking. This helps prevent accidents during operation. Yet, operators must remain vigilant and aware of their surroundings. Distractions can lead to mistakes. Continuous evaluation of safety practices is necessary to fully harness the benefits of this equipment.

When using a standing pallet jack, safety should always be a top priority. It's essential to wear appropriate footwear with good traction. Slippery surfaces can lead to accidents. Make sure you can control the jack comfortably and navigate your workspace carefully. A sudden slip can result in serious injury.

Before operating the pallet jack, inspect it for damage. Check the wheels and brakes to ensure they function properly. Leaving a damaged jack in service is risky. If you notice any issues, report them immediately. Avoid overloading the pallet jack; respect the weight limits. Distributing weight evenly can prevent tipping.

In addition, be aware of your surroundings. Look out for obstacles that may hinder your movement. Corners and tight spaces can be particularly tricky. Even small distractions can lead to accidents. Lastly, remember to engage the brake when stationary. Neglecting this can lead to unwarranted rolling. Reflect on these aspects for a safer, more efficient experience.