Leave Your Message

In the world of material handling, the "Straddle Pallet Jack" is a game-changer. Industry expert John Smith states, "Straddle Pallet Jacks provide greater versatility and efficiency in tight spaces." These tools enable workers to move pallets without needing ample floor space. Their unique design balances loads securely while traversing various terrains.

Straddle pallet jacks are more than mere equipment. They enhance productivity and safety in warehouses. However, they also require proper training. Lack of training can lead to accidents, reminding us of their complexities. Operators must be aware of inherent risks. Even with advanced features, manual handling remains critical.

Thorough understanding of how a Straddle Pallet Jack operates is essential. It’s not just about lifting pallets but doing so efficiently and safely. Reflection on operational practices could lead to improvements in safety and productivity. Adapting to these nuances ensures your team maximizes the benefits of this valuable machine.

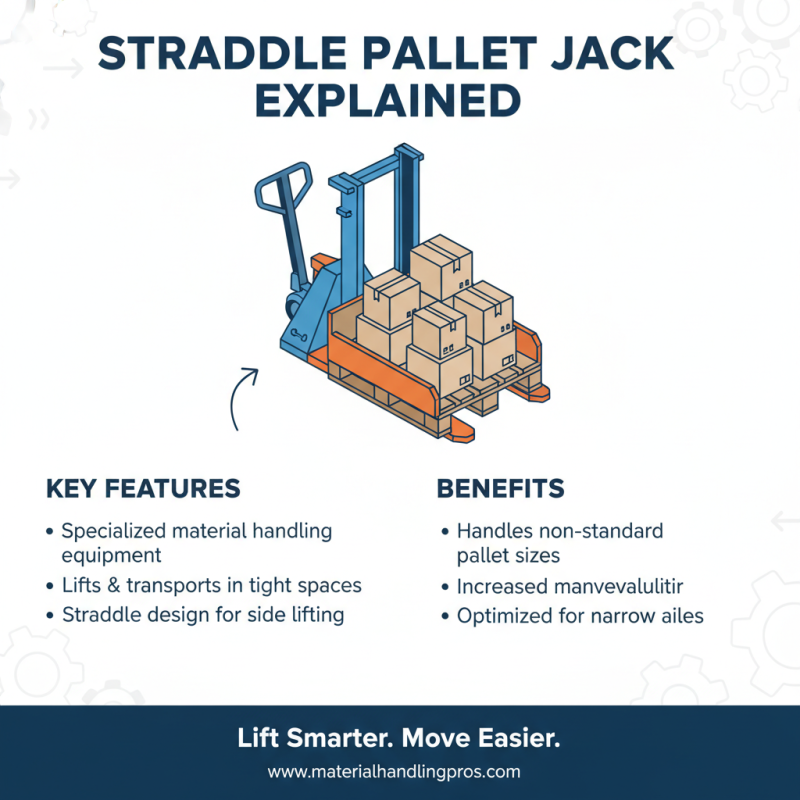

A straddle pallet jack is a specialized piece of material handling equipment. It is designed to lift and transport pallets in tight spaces. The key feature of the straddle pallet jack is its straddle design. This allows the jack to lift pallets from the sides rather than underneath. This is particularly useful for handling non-standard pallet sizes.

The straddle pallet jack has wheels that are positioned to straddle the pallet. This means it can easily maneuver in narrow aisles. Users appreciate its compact design, which facilitates better storage efficiency. However, not all models are created equal. Some may struggle with stability under load. Be cautious when lifting heavy items.

Tip: Always check the weight limit before operating. Overloading can lead to accidents.

The control mechanism lets operators lift and lower pallets smoothly. Still, it requires practice to master. Improper handling can cause damage to products or equipment.

Tip: Regular maintenance is crucial. Check hydraulic fluid levels frequently to ensure the jack operates smoothly. Adjust brakes as needed to retain control.

A straddle pallet jack is designed for lifting and transporting pallets efficiently. Its key components include the frame, wheels, and forks. Understanding these parts can enhance its usage and ensure safety.

The frame supports the entire structure. It is crucial for stability during operations. The wheels, typically made from durable materials, allow easy maneuverability. They enable the jack to glide smoothly across different surfaces. The forks extend to lift heavy loads. Their adjustable width accommodates various pallet sizes, which is essential for versatility.

While using a straddle pallet jack, operators must ensure proper maintenance. Regular checks on the wheels and forks help prevent mishaps. Operators should reflect on their techniques for safe maneuvering. Overloading can lead to mishaps, so attention to weight limits is vital. Ultimately, understanding these components and their functions can lead to more efficient warehouse operations.

A straddle pallet jack is a versatile tool designed for handling pallets. Its unique design allows it to straddle the load. This feature enables it to lift pallets that may be wider than standard designs.

The operational mechanism is quite interesting. It uses a hydraulic system for lifting. Operators can raise or lower the fork with a simple push of a lever. The wheels allow for smooth movement across warehouse floors. However, maneuvering in tight spaces can be challenging. The operator needs to be cautious to avoid collisions with nearby items.

While effective for heavy lifting, there can be potential pitfalls. Operators must ensure the load is balanced. An unbalanced load can lead to tipping. Understanding the weight limit is crucial. Also, training is essential to prevent accidents. Engaging workers in the operational process often leads to better handling practices.

| Feature | Description |

|---|---|

| Design | A straddle pallet jack has a unique design featuring two arms that straddle the pallet, allowing the user to lift it securely from both sides. |

| Lifting Capacity | Typically, straddle pallet jacks can lift between 2000 to 5000 pounds, depending on the specific model and manufacturer. |

| Operation | Operated manually or electrically, the pallet jack uses hydraulic mechanisms to lift the pallet, allowing ease of movement around a warehouse. |

| Usage Scenarios | Ideal for narrow aisles in warehouses, shipping departments, and loading docks where traditional fork lifts would be impractical. |

| Safety Features | Includes safety features such as emergency brakes, hand protection, and load stabilizing mechanisms to enhance operator safety. |

| Maintenance | Regular maintenance includes checking hydraulic oil levels, inspecting wheels, and ensuring all moving parts are lubricated for optimal functionality. |

Straddle pallet jacks have gained popularity in warehousing due to their unique design and functionalities. Unlike traditional pallet jacks, these machines straddle the load. This allows them to lift and transport heavier pallets with greater stability. According to industry reports, straddle pallet jacks can increase productivity by up to 25%. This efficiency enables businesses to streamline their operations significantly.

One of their standout advantages is versatility. Straddle pallet jacks can handle various pallet sizes. This adaptability makes them suitable for different products. Some reports suggest that warehouses utilizing these jacks experience fewer damages during transportation. However, it’s essential to train staff properly. Many accidents occur due to improper use.

Improving workflow is crucial in today’s fast-paced environment. Straddle pallet jacks play a vital role in that. They can move items over longer distances effortlessly. Even with efficiency, they require maintenance checks and operator care. This ongoing need can be a challenge for some warehouses. Balancing productivity and safety is key.

Straddle pallet jacks are widely used in warehouses and manufacturing facilities. They allow the lifting of heavy loads while accommodating various pallet sizes. In industries where space is limited, these machines excel. They maximize efficiency by minimizing the time spent maneuvering goods.

According to a study by the Material Handling Industry of America, straddle pallet jacks can improve loading times by up to 25%. This efficiency leads to better inventory management. Studies show that companies often reduce labor costs significantly when integrating these jacks into their operations. However, operators need training. Safety concerns can arise if users are inexperienced.

Moreover, performance metrics reveal that the use of straddle pallet jacks can increase throughput. A report from the National Institute of Standards and Technology highlights that proper usage can boost productivity by about 30%. However, it’s essential to assess ongoing maintenance needs. Neglect can lead to inefficiencies. The benefits are clear, but awareness of proper operation is vital for success.