Leave Your Message

In the world of material handling, Double Pallet Jacks are becoming increasingly indispensable for businesses looking to enhance efficiency and productivity. According to a recent industry report by the Material Handling Industry of America (MHIA), the demand for pallet jacks has surged by 25% over the past three years, driven by the rise of e-commerce and the need for seamless inventory management. However, as the market expands, so do the complexities associated with selecting the right equipment. Understanding the technical specifications of these essential tools is crucial for global buyers, as variations in capacity, fork length, and maneuverability can significantly impact operational performance.

This blog aims to illuminate the key considerations and potential pitfalls in the selection process, providing insights to ensure that businesses make informed purchasing decisions when investing in Double Pallet Jacks.

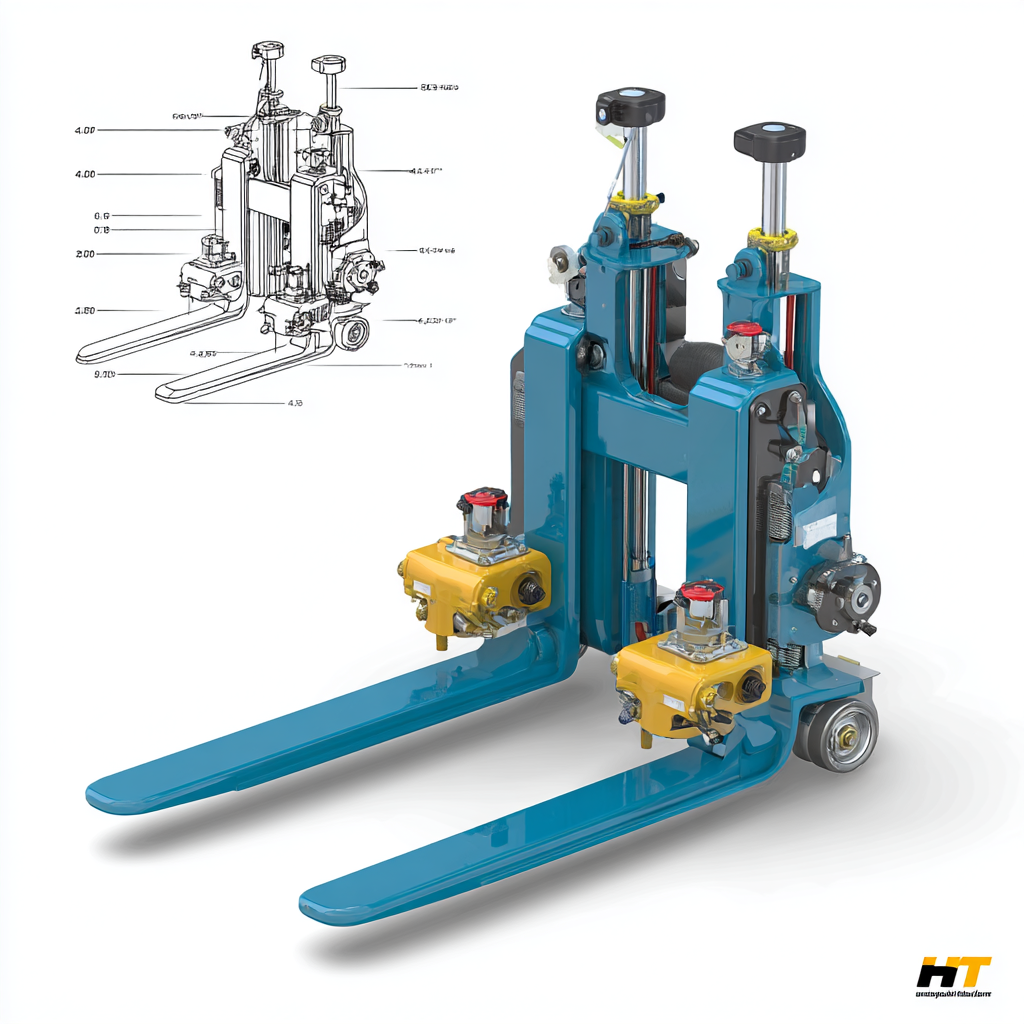

When purchasing double pallet jacks for global markets, it’s essential to consider several key specifications that impact their performance and durability. According to a report by MarketsandMarkets, the global material handling equipment market is projected to reach $200 billion by 2026, highlighting the growing importance of efficient equipment such as double pallet jacks. Buyers should prioritize factors such as load capacity, typically ranging from 4,400 to 8,800 pounds, as this will directly affect the efficiency in transporting goods within warehouses and distribution centers.

Another critical specification is the fork width and length, which can vary widely depending on operational needs. Industry standards suggest forks of 27-30 inches in width and lengths of 48-60 inches to accommodate different pallet types globally. Additionally, examining the wheels and their material is crucial; for instance, polyurethane wheels offer superior traction and reduce floor damage, leading to additional savings in maintenance. Selecting a double pallet jack with adjustable features and ergonomic design can also support operator comfort, ultimately influencing productivity. By focusing on these specifications, global buyers can ensure they select a pallet jack that meets both their operational demands and the standards of international logistics.

In the world of material handling, choosing between manual and electric double pallet jacks is essential for optimizing efficiency. Manual double pallet jacks, while cost-effective and straightforward, require physical effort to operate. This can lead to fatigue during long shifts, especially in environments with frequent lifting and transporting tasks. However, their mechanical simplicity allows for more straightforward repairs and maintenance, making them appealing to businesses with limited budgets or less intense workloads.

In the world of material handling, choosing between manual and electric double pallet jacks is essential for optimizing efficiency. Manual double pallet jacks, while cost-effective and straightforward, require physical effort to operate. This can lead to fatigue during long shifts, especially in environments with frequent lifting and transporting tasks. However, their mechanical simplicity allows for more straightforward repairs and maintenance, making them appealing to businesses with limited budgets or less intense workloads.

On the other hand, electric double pallet jacks represent a significant advancement in efficiency and ease of use. By minimizing physical strain, these powered devices enable workers to move heavy loads with minimal effort. They often come equipped with features such as adjustable speed settings and advanced maneuverability, which enhances productivity in busy warehouses. Additionally, electric models may include safety features, such as automatic braking and load sensors, reducing the risk of accidents and injuries. For companies aiming for peak efficiency and reduced labor costs, investing in electric double pallet jacks may be the key to achieving a more streamlined operation.

When selecting a double pallet jack, understanding load capacity is crucial for ensuring efficiency and safety in your operations. Load capacity refers to the maximum weight that a pallet jack can safely carry, and it is typically measured in pounds or kilograms. Industry standards dictate that a reliable double pallet jack should support at least 5,500 pounds, making it essential for handling larger quantities of goods simultaneously. Buyers should evaluate their needs based on the types of products they handle and choose a pallet jack that exceeds their maximum load requirements.

**Tip:** Always check the manufacturer's specifications for load capacity and ensure it meets your operational demands. Overloading your equipment can lead to accidents and damage, resulting in costly downtime.

Additionally, consider the dimensions of the pallets you will be using. Many standard pallets are 48 x 40 inches, but some operations might utilize different sizes. A double pallet jack designed for versatility will accommodate various pallet dimensions, making it a worthwhile investment for businesses aiming to optimize their warehouse efficiency.

**Tip:** Before purchasing, test different models with your actual pallets to ensure proper fit and functionality. This hands-on approach will help you select the best double pallet jack for your specific logistics needs.

| Model | Load Capacity (lbs) | Fork Length (inches) | Width (inches) | Weight (lbs) | Material |

|---|---|---|---|---|---|

| Model A | 5500 | 48 | 27 | 150 | Steel |

| Model B | 6600 | 54 | 28 | 160 | Aluminum |

| Model C | 5000 | 48 | 30 | 145 | Steel |

| Model D | 7000 | 60 | 29 | 180 | Composite |

When selecting a double pallet jack, the importance of fork dimensions and width cannot be overstated. Various industry reports indicate that the ideal fork width ranges from 540mm to 685mm, optimizing load stability and maneuverability in tight spaces. According to a 2022 Material Handling Equipment Manufacturers Association (MHEDA) study, pallet jacks with wider forks provide increased efficiency for double-stacked pallets, ultimately reducing handling time by up to 30%. This is particularly relevant for global buyers who often operate in diverse warehouse environments.

The choice of fork length also plays a crucial role in the overall efficacy of pallet jacks. Standard fork lengths typically range from 1,000mm to 1,200mm, accommodating a variety of pallet sizes. A report from the International Warehouse Logistics Association (IWLA) emphasizes the necessity for adaptable equipment, noting that double pallet jacks with longer forks significantly enhance loading efficiency by allowing operators to handle larger loads without additional equipment. As global supply chains become increasingly interconnected, understanding these technical specifications will be essential for buyers aiming to optimize their operations.

When investing in a double pallet jack, understanding not only its technical specifications but also how to maintain it is crucial for ensuring longevity. Proper maintenance can extend the lifespan of your equipment, saving you money in the long run. Simple yet effective maintenance practices can keep your pallet jack running smoothly and efficiently.

Regular inspections are key. Check the hydraulic oil levels and ensure that there are no leaks in the hydraulic system. Keeping the wheels clean and free from debris will also prevent wear and tear. It’s advisable to lubricate moving parts to enhance their efficiency and avoid rust. By incorporating these practices into your routine, you can significantly reduce the risk of unexpected breakdowns.

Additionally, training your operators on proper usage is essential. Misuse can lead to rapid deterioration of your double pallet jack. Ensure that operators are aware of weight limits and the correct handling procedures when maneuvering heavy loads. This not only guarantees the safety of the workers but also protects the investment in your equipment. With these tips in mind, maintaining your double pallet jack becomes a straightforward task, ultimately contributing to its durability and performance.

This chart illustrates the weight capacity of various double pallet jack models, showcasing the differences among them. Understanding these specifications can help global buyers make informed choices when investing in pallet jacks for their businesses.