Leave Your Message

In the fast-paced world of logistics and warehouse management, the right tools can significantly enhance operational efficiency. The End Rider Pallet Jack, a vital piece of equipment in material handling, is designed to improve not just performance but also safety in various industrial applications. According to a report by Grand View Research, the global pallet jack market is projected to reach $2.5 billion by 2025, driven by increased demand for automation and efficient warehouse operations. This underscores the necessity for organizations to invest in high-quality equipment that meets their specific needs. Understanding the technical specifications of the best End Rider Pallet Jack is crucial for achieving optimal performance, reducing downtime, and maximizing productivity in any warehouse setting. In this blog, we will explore key features, tips, and insights to help you select the ideal End Rider Pallet Jack for your operations.

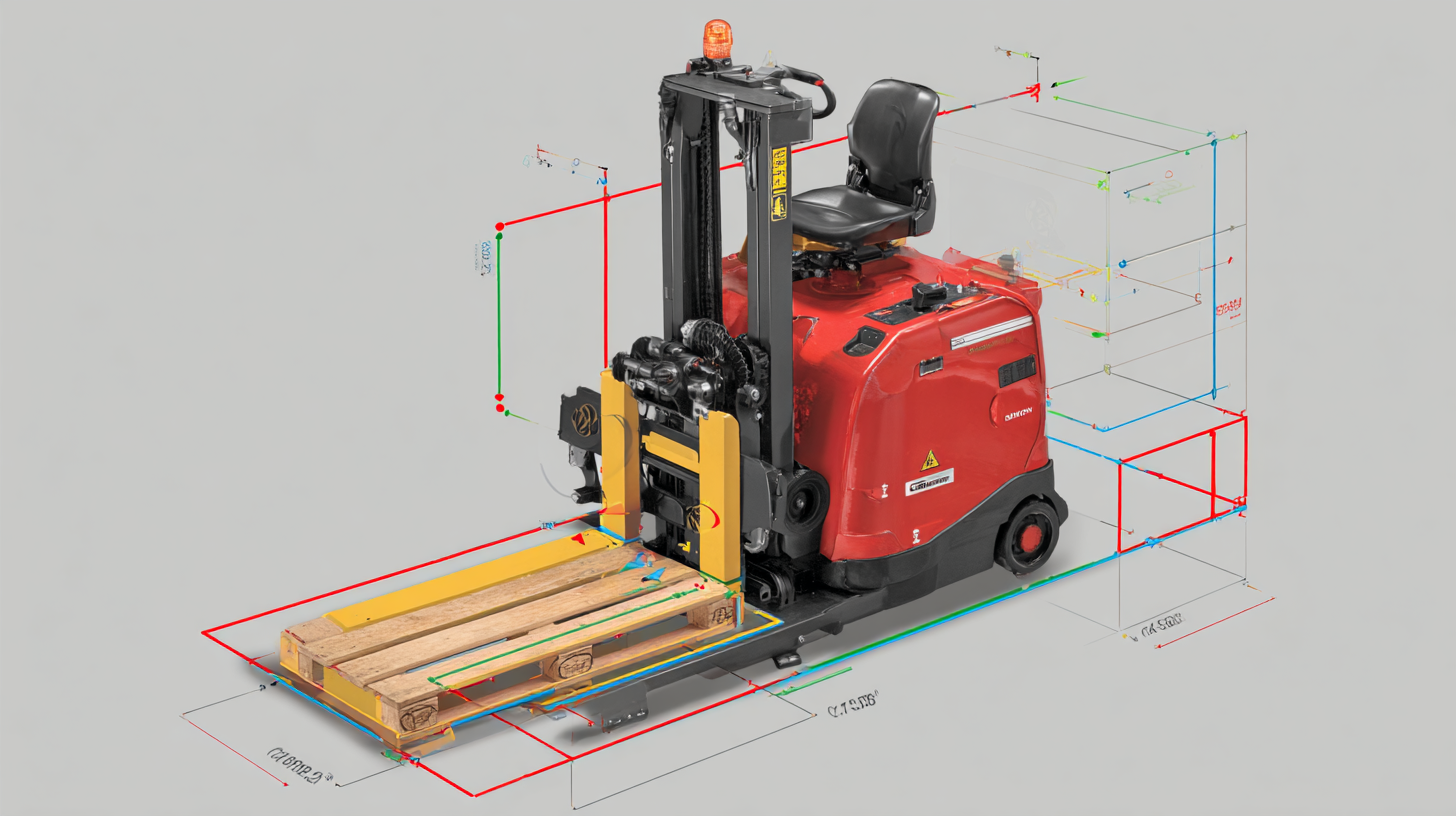

When choosing the best end rider pallet jack for optimal efficiency, it's essential to focus on several key features that can significantly enhance performance. One critical aspect is the power source; electric models are increasingly popular due to their zero-emission design and lower maintenance costs. Opting for a pallet jack power technology that suits your warehouse's operation can lead to streamlined workflows and reduced operational costs.

Another important feature to consider is the ergonomic design of the pallet jack. Models designed with operator comfort in mind can help alleviate strain during use, which translates to increased productivity over extended periods. Look for jacks that offer adjustable handlebars and easy-to-reach controls.

Tips for maximizing efficiency include regularly maintaining the equipment to avoid downtime, training operators on best practices for handling the pallet jack, and ensuring the right specifications align with your handling needs. Additionally, investing in features like advanced safety systems can protect both the operator and the goods being transported, facilitating a safer working environment.

| Specification | Details |

|---|---|

| Max Load Capacity | 5000 lbs |

| Fork Length | 48 inches |

| Overall Width | 27 inches |

| Turning Radius | 58 inches |

| Maximum Lift Height | 7.5 inches |

| Control Type | Electric |

| Power Source | 24V Battery |

| Weight | 600 lbs |

| Wheel Type | Polyurethane |

| Braking System | Electromagnetic |

When selecting an end rider pallet jack, understanding load capacity and lift height is paramount for optimal performance in any warehousing environment. According to a report by the Material Handling Industry of America (MHIA), pallet jacks with higher load capacities—typically ranging from 4,500 to 6,000 pounds—are essential for facilitating efficient operations in a busy warehouse. These models can handle heavy pallet loads while ensuring safety and stability during transportation. For instance, Elite Models offer a load capacity of up to 5,500 pounds, which is crucial for sectors like retail and manufacturing where heavier items are frequently moved.

In addition to load capacity, lift height plays a significant role in determining the operational efficiency of end rider pallet jacks. A study by the Industrial Truck Association highlights that models with lift heights exceeding 6 feet are ideal for accessing high-storage racks, thereby maximizing vertical space in warehouses. Brands like Crown and Raymond are known for engineering pallet jacks that can achieve impressive lift heights, catering to businesses that require flexibility and efficiency in their storage practices. The combination of these specifications ensures that operators can maneuver through tight aisles and efficiently handle all types of loads, directly impacting productivity and workflow in any logistics setting.

When selecting the best end rider pallet jack, the importance of durability and build quality cannot be overstated. A well-constructed pallet jack will not only withstand the rigors of daily use but also resist wear and tear over time. This is essential for maintaining productivity in warehouses and distribution centers. Look for models made from high-grade materials, such as steel or heavy-duty polymer, which can handle heavy loads while providing stability and safety.

Tips for ensuring durability include regular maintenance checks and proper usage training for operators. A well-trained operator will avoid unnecessary strain on the equipment, extending its lifespan. Additionally, consider pallet jacks with sealed bearings and rust-resistant finishes to further enhance longevity.

Investing in a pallet jack that prioritizes build quality means fewer replacements and repairs, translating to cost savings in the long term. When choosing your equipment, examine the welds, joints, and overall design. A robust design often leads to better performance, allowing your operations to run smoothly and efficiently.

In the fast-paced logistics and warehousing industries, the evolution of pallet jacks has been significantly influenced by innovative technologies aimed at enhancing performance. Modern end rider pallet jacks now incorporate advanced features such as electric power steering and regenerative braking systems, which not only improve maneuverability but also increase energy efficiency. According to a recent industry report by the Material Handling Industry of America (MHIA), implementable technologies can boost a pallet jack's operational efficiency by up to 25%, leading to substantial time and cost savings in daily operations.

Moreover, the integration of smart technologies has transformed traditional pallet jacks into sophisticated material handling solutions. Features like real-time load monitoring, GPS tracking, and analytics enable operators to optimize their logistics processes. According to a survey conducted by the Warehousing Education and Research Council (WERC), businesses that adopted smart pallet jacks reported a 30% reduction in downtime compared to those using conventional models. These enhancements not only elevate performance but also contribute to a safer working environment by minimizing the risk of accidents associated with manual handling.

This chart illustrates the comparison of key performance metrics of modern end rider pallet jacks based on their lifting capacity, average speed, and operational efficiency.

Maintaining your End Rider Pallet Jack is essential for ensuring optimal performance and longevity. Regular maintenance not only helps to prevent costly breakdowns but also enhances the efficiency of your operations. One critical aspect is to regularly check and maintain the battery, ensuring it is charged, clean, and free from corrosion. Keeping the battery terminals clean will significantly improve performance and lifespan. Additionally, monitor the hydraulic fluid levels and replace it according to the manufacturer’s recommendations to prevent system failures.

Maintaining your End Rider Pallet Jack is essential for ensuring optimal performance and longevity. Regular maintenance not only helps to prevent costly breakdowns but also enhances the efficiency of your operations. One critical aspect is to regularly check and maintain the battery, ensuring it is charged, clean, and free from corrosion. Keeping the battery terminals clean will significantly improve performance and lifespan. Additionally, monitor the hydraulic fluid levels and replace it according to the manufacturer’s recommendations to prevent system failures.

Another vital maintenance tip involves inspecting the wheels and forks routinely. Debris and damage can lead to poor maneuverability and increase wear and tear. Ensure the wheels are free of blockages and rotated properly. Lubricate moving parts like pivot points and wheel axles to reduce friction and prevent premature wear. Lastly, conducting regular inspections and following the manufacturer’s service guidelines are key to extending the lifespan of your End Rider Pallet Jack, ultimately saving time and money in the long run.